Syntegon recently presented its new line concept for liquid pharmaceuticals at Pharmatag 2025, designed to addresses the challenges of high performance, availability, maximum product yield and minimal operator intervention.

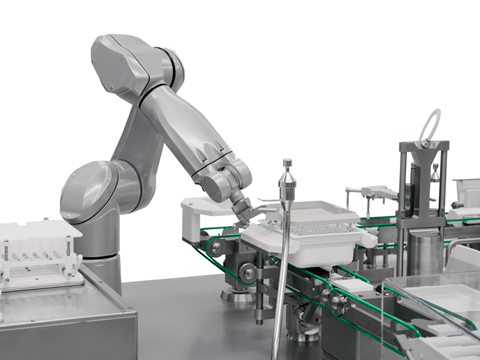

Developed in collaboration with pharmaceutical industry partners, it features a gloveless isolator aiming to allow pharmaceutical manufacturers to automate their processes and minimize human intervention. “But we go one step further with SynTiso: the robots are generally located as far away from the process as possible and are only used for aseptic setup and as needed,” explains product manager Markus Heinz.

Apparently, this provides customers with an Annex 1-compliant solution including the First Air principle, which allows air to circulate freely. “The position of the robots also minimizes particles in the aseptic area, which in turn significantly reduces the risk of contamination,” adds Heinz. Real-time monitoring of germs and particles also eliminates the need to exchange settle plates.

The new contactless, suspended transport is said to generate no particles and facilitate cleaning and maintenance even with potent pharmaceuticals such as oncological drugs, due to a smaller number of components within the isolator. Syntegon says the system ensures faster aseptic transport and up to 50% shorter batch changeovers in a smaller space. With 100% in-process control (IPC), the company claims SynTiso can process up to 600 syringes, vials, or cartridges per minute.

Earlier this year the company announced it would be presenting its new handling solution for cookie packaging, the Syntegon FGCT count feeder, at the iba trade fair in Düsseldorf. The feeder is said to have gentle handling, is carefully balanced at high speed, guarantees an efficient packaging process and avoids product damage.

In April, Syntegon revealed a new filling machine for ready-to-use nested syringes, reportedly offering a safe output of up to 400 syringes per minute with 100% in-process control. The MLD Advanced’s automatic bag and tub openers are designed to utilize aseptic, no-touch transfer to move syringes into the filling area.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet