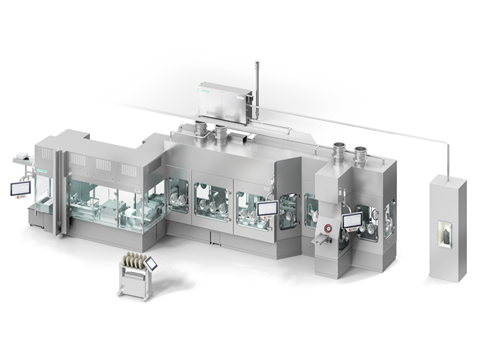

Syntegon has revealed a new filling machine for ready-to-use nested syringes, reportedly offering a safe output of up to 400 syringes per minute with 100% in-process control.

The MLD Advanced’s automatic bag and tub openers are designed to utilize aseptic, no-touch transfer to move syringes into the filling area. There Syntegon’s Pharma Handling Unit automatically denests the syringes, avoiding glass-to-glass contact, and puts the containers into the pitch adjustment station.

At this point, the syringes are moved into the machine pitch and placed in the clips of the machine transport.

“This unique clip system is the first key feature we adopted for syringe applications from the cartridge line,” says Markus Burkert, product manager at Syntegon. “The special circulating transport system ensures smooth transportation and is therefore ideal for RTU syringes, as well as vials and cartridges.”

Before they are transferred to the filling station, the empty syringes are weighed with 100% in-process control. In a filling and stoppering process based on the FXS series for syringes, the filling needles are mounted on the Pharma Handling Unit – flexible redosing is possible if required – and the filling weight is precisely controlled.

Once the stopper has been inserted with a vacuum or vent tube, the circulating transport system returns the containers and the Pharma Handling Unit places them back into their nexts.

“Especially with high-value medicines, it is essential that each drop is filled and weighed optimally,” explains Burkert. “That’s why we have combined the MLD platform, which was previously used primarily for cartridges and vials, with our technologies for syringe filling.”

“In addition to minimizing product loss, an important focus is on providing documented proof about the weighing of each container,” continues senior product manager Klaus Ullherr. “This gives manufacturers the certainty that all containers have been filled correctly.

“This way, we can offer our customers a seamless process for their pre-sterilized syringes from a single source.”

“By using tried and tested technologies, the machine is available quickly, and the risk is significantly reduced,” adds Burkert.

Reportedly, a European pharmaceutical manufacturer is already set to utilize the first MLD Advanced to process and fill ready-to-use syringes.

Late last year, TurboFil unveiled its TipFil Syringe Filling & Assembly Machine – a solution designed to automate every process from syringe loading, filling and capping through inspection, labeling and printing. It was expected to reach throughput speeds of up to 80 syringes per minute.

Since then, Syntegon has launched the Pack 103, its entry-level flow wrapping machine geared towards small and medium-sized businesses. Designed for ease of use and efficiency, it claims to reach an output of up to 175 packs per minute.

If you liked this story, you might also enjoy:

Reuse vs. single use – which is better for the environment?

Sustainable Innovation Report 2025: Current trends and future priorities

What can the world learn from South Korea’s world-leading performance in plastics circularity?

No comments yet