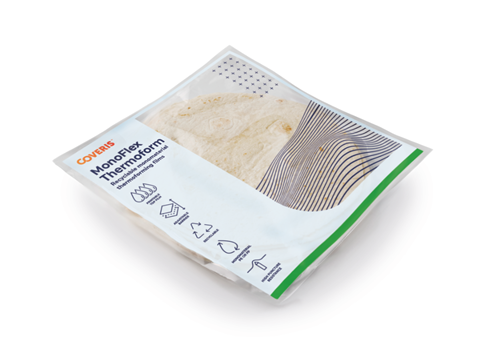

Coveris has launched its MonoFlex Thermoform film packaging for tortilla wraps, a mono-material solution designed to replace non-recyclable, mixed material thermoforming substrates while maintaining a long shelf life.

Coveris says the project is the result of close cooperation with a tortilla wrap manufacturer, seeking a more sustainable alternative to the previously used PA/PE structure. The primary challenge was identifying a recyclable material while ensuring a minimum six-month shelf life for a tortilla, with a low quantity of preservatives.

Following performance testing at Coveris’ Food Science Lab in Gainsborough, UK, the team selected a mono-material based top and base thermoforming film, said to successfully protect the tortilla wraps against mould throughout the required testing period while enabling recycling in the same waste stream.

According to Coveris, key benefits of the packaging solution include advanced barrier properties for extended product protection and shelf-life and strong puncture resistance. It adds that MonoFlex Thermoform allows a ‘seamless’ switch on the packing lines from alternative substrates, maintaining compatibility with existing packing lines without compromising packaging speeds.

Available as fully printed or unprinted top and base film, the packaging supports conventional and HD flexographic or rotogravure print with options for matt, gloss and tactile lacquer finishing, aiming to enhance consumer appeal and produce an attractive on-shelf presentation.

Last month Coveris Rypin collaborated with Polish brand Brześć to package its ‘puffs’ snacks in a recyclable film, said to improve shelf appeal and support the reduction of packaging waste. It is also optimized for eight-colour flexographic printing with optional matt or gloss finishes, drawing attention to the brand identity.

Amcor recently unveiled its bespoke tray for French manufacturer Cofigeo’s single-serve ready meals range, said to conform to Design for Recycling guidelines and offer a lightweight mono-material polypropylene (PP) construction, suitable for collection and reprocessing in France’s recycling infrastructure. Amcor says it devised a tray with different sized compartments that considered the various sizes, textures and densities of the ingredients.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet