A strategic partnership between Volpak and Watttron intends to integrate intelligent digital sealing technology into horizontal pouching machinery in a step towards precise, efficient, and sustainable flexible packaging processes.

Volpak is combining its pouching machinery with Watttron’s intelligent sealing technology in pursuit of an advanced digital sealing solution that can be easily retrofitted onto existing machinery. Bringing the technologies together is expected to allow Volpak’s customers to improve their sealing quality, cut down on material waste, and benefit the environment.

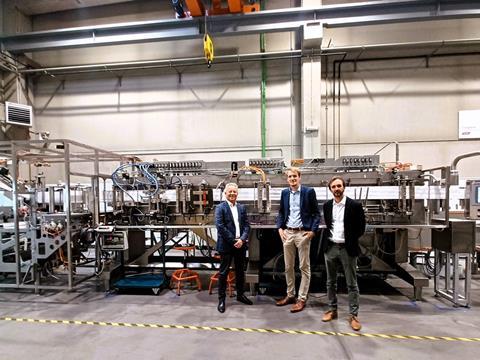

As a Coesia Company, Volpak has also worked with R.A Jones to enhance its ultra-high speed horizontal pouching machinery – which apparently runs up to 2000 pouches per minute – with integrated Watttron digital sealing technology. The partners report that machines featuring Watttron seal bars are operating at major FMCG producers in Europe and the USA.

Both Volpak and R.A Jones are running production-scale laboratory machinery with Watttron technology, which is now available for customer film trials and testing.

The announcement comes after Mespack signed its own agreement with Watttron to integrate smart digital sealing technology into its flexible packaging machinery.

Last year’s interpack trade show also saw a range of developments in sealing technology, from SN Maschinenbau’s horizontal pouch machines, which sealed UPM Specialty Papers’ heat-sealable barrier papers, to Syntegon’s GKB 2100 banding machine for sealing hard gelatin and cellulose-based capsules.

If you liked this article, you might also enjoy:

The L’Oréal approach to packaging sustainability

The way we talk about plastic needs to change – here’s how to get it right

What steps is Apple taking to make its packaging more sustainable?

No comments yet