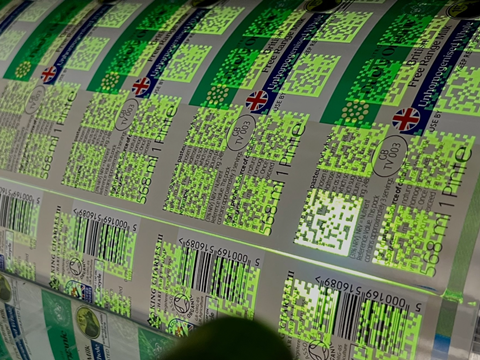

Polytag, Saica Flex, and Paragon Inks have teamed up to print invisible UV tags on packaging labels and track item-level recycling data in line with environmental legislation and reporting requirements.

Each label is printed with an invisible tag using Paragon’s UV inks. Polytag’s detection systems can scan the labels and capture real-time, item-level data as the packaging moves through the recycling stream.

“Creating the UV inks was a technical challenge,” explained Barbara Paterson, technical director at Paragon Inks. “They needed to remain detectable by Polytag readers across a wide range of colours, substrates, and packaging formats, even after packaging has been crushed or otherwise processed.

“At the same time, the inks had to meet strict food-safety and environmental requirements. Two years of development, testing, and iterative validation went into delivering a solution that is reliable, safe, and fully compatible with existing waste management operations.”

Recyclers can use the label data to track which of their products enter the recycling stream, measure recovery rates, and share this information with the relevant brands – as well as to prove their compliance with regulations like Extended Producer Responsibility.

Additionally, the labels can be chipped down or separated through flotation. Any residual ink is believed to behave in line with other approved UV products and avoid contaminating recovered materials.

“Seeing the labels generate real data in a live waste stream validates all the work that went into development,” commented Martin Fowler, global sales director at Paragon Inks. “It proves the system works as intended, and this is just the beginning - the potential for other products and sectors is enormous.”

Brands like Waitrose, Marks & Spencer and Ocado are already using UV tags to track recycling data for their milk cartons. However, the partners emphasize that the UV label solution is compatible with multiple packaging formats across a ‘wide range’ of consumer goods – emphasizing that the technology integrates ‘seamlessly’ and ‘cost-effectively’ into existing packaging and printing workflows.

“We knew from the start that adoption would depend on keeping things simple,” said Francisco Barrera, Sales & Marketing director at Saica Flex. “Brands need solutions that fit naturally into their operations and current production environments.

“This product works across the entire packaging lifecycle, from printing through recycling with minimal disruption. It gives brands meaningful insight, while remaining practical and viable even for high-volume products like milk cartons.

“Through this collaboration, we’re giving brands insight and control over their environmental performance, making recycling measurable, actionable, and scalable. It’s a real game-changer for the industry, and we encourage more brands to embrace this solution to make a tangible, positive impact on the circular economy.”

“And because it’s built on GS1 global open standards, the UV tag solution is ready to scale across multiple sectors and applications, allowing brands and recyclers to participate fully in building a transparent circular economy,” continued Polytag CEO Alice Rackley.

In a similar development, Polytag recently implemented Zebra Technologies Corporation’s Aurora Vision Library software into its UV labelling solution. The software is anticipated to read 2D codes on high-speed conveyor lines in dimly lit facilities and accurately process 20 frames per second.

It has also worked with Pellenc ST to combine advanced sorting technology with invisible UV watermark-based tracking. The two companies have implemented a sorting prototype in Pellenc ST Innovation Center and validated it to TRL 7.

If you liked this story, you might also enjoy:

The ‘complex reality’ of reusable packaging in Europe

Single-use packaging versus reusable packaging: Which is more sustainable?

The ultimate guide to global packaging sustainability regulation

No comments yet