Pellenc ST and Polytag have joined forces to combine advanced sorting technology with invisible UV watermark based tracking, aiming to improve material recovery and traceability throughout the recycling process.

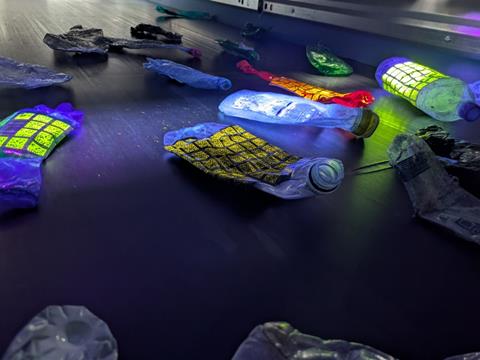

The partnership seeks to enable real-time tracking and optimization of packaging waste through the recycling process, from Materials Recovery Facilities to recyclers. Each packaging item is embedded with invisible printed UV watermarks in the form of a GS1 open standard data matrices.

Apparently, as a packaging item enters the recycling stream, a detection unit instantly captures its associated data. The system then executes precise sorting actions based on near-infrared (NIR) spectroscopy and UV watermarks.

The two companies hope to provide recycling facilities with new capabilities to detect and sort waste streams. By embedding smart data at barcode level directly into packaging materials, the collaboration aims to empower waste management companies and brand owners with control over the recycling journey of their products, ensuring packaging stays within the circular economy.

Pellenc ST and Polytag have implemented a sorting prototype in Pellenc ST Innovation Center and validated it to TRL 7. In addition, Pellenc ST says it plans to manufacture UV reader modules.

Last year the HolyGrail 2.0 Initiative announced the successful validation of digital watermarking technology in combination with NIR for advanced sorting of flexible packaging. Focusing on the separation of hygiene-grade LDPE films and food-grade PP films, advanced sortation using digital watermark technology from Digimarc and add-on module from Pellenc ST was successfully validated in an industrial setting at Hündgen Entsorgung’s material recovery facility (MRF) for separating flexible packaging.

In related news, Glacier revealed in April that it had raised $16 million in a Series A funding round for its AI robots, designed to improve recovery and purity rates in the recycling process. Glacier’s system uses advanced computer vision and smart robotic arms to identify and sort materials ranging from PET plastic and aluminium cans to toothpaste tubes and cat food tins.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet