SiOPack claims to have developed a fully recyclable, food-safe, and plastic-free packaging window made from paper – a move hoped to reduce plastic waste without compromising on product visibility.

Conventionally, packs that require visibility – even those otherwise made from paper – use plastic for their transparent components. Europe is thought to use over 150,000 tonnes of plastic to produce bakery bag windows every year.

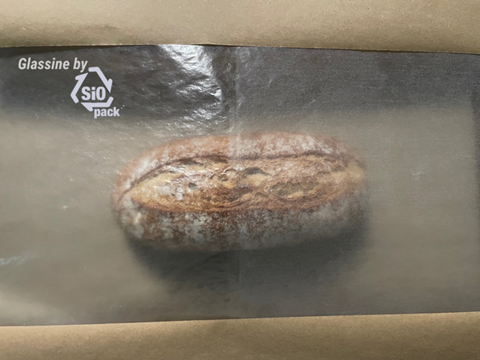

In response, SiOPack worked with technology experts at Nanopool to create its Glassine solution. This involves applying a patent-pending, liquid-based barrier coating (either inline during the manufacturing stage or offline using standard flexographic printing equipment) to glassine, which is traditionally opaque.

This process is said to result in a material that is both transparent and resistant to air and moisture, all in one layer; it does not require lamination or additional plastic films. It is described as ‘breathable’ and reportedly keeps products fresh, but it can also be recycled in existing paper streams at end-of-life.

Customers can apparently implement the material into their packaging processes without disrupting their supply chains. According to SiOPack, making the switch can help companies demonstrate their sustainability commitments to consumers.

In a recent pilot project with a major retailer, SiOPack replaced the plastic windows used in bakery bags with its Glassine product. It was said to maintain the same visibility, hygiene, and product freshness as traditional plastic while also improving theft prevention at self-checkouts, since the product remained fully visible.

Other potential applications include stand-up pouches for dried goods and cereals; sachets for cosmetics, detergent pods, or refills; pharmaceutical packaging for herbal remedies or teas; and secondary packaging for e-commerce and branded goods.

“The time is right because the pressure is real,” comments the Siopack team. “And now, there’s finally a paper-based solution that doesn’t force a trade-off between visibility and sustainability.”

All the way back in 2022, Mondi and Fiorini International pursued a similar goal by creating a paper bag with a transparent, recyclable and biodegradable cellulose window for Antico Pastificio Umbro’s pasta products.

YUTOECO went on to convert cellulose substrate into a transparent, plant-based film for food-safe applications such as visible lunchboxes, baking packets, and pharmaceutical packaging; it also sought to phase out plastics while maintaining visibility.

More recently, Sabert Europe unveiled its dual-ovenable Hot2Go pack. Designed for on-the-go servings of hot food, it enables customers to implement a high-clarity rPET window, said to come with a guaranteed minimum of 30% recycled content.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet