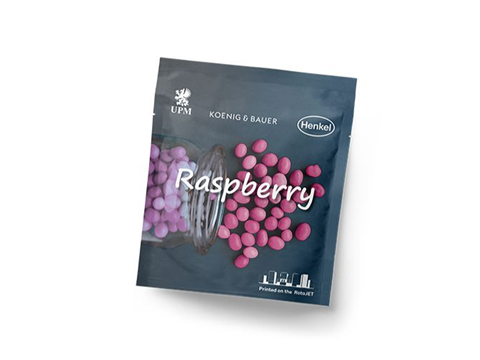

UPM Specialty Papers, Henkel, and Koenig & Bauer have conceptualized a heat-sealable ’doypack’ confectionary pouch, bringing together recyclability, high barrier properties, and suitability for both traditional and digital printing methods.

At the beginning of the project, the UPM Asendo barrier paper was tested and optimized on Koenig & Bauer’s RotaJET digital press. UPM highlights that, unlike flexo, rotogravure, and offset printing methods, digital print can produce small batches for events, localized packaging, and other specific market purposes.

Henkel’s AQUENCE EPIX BC 6134 FL coating was then used to coat the prototype pack. This is set to unlock grease- and moisture-resistance alongside ‘excellent’ sealing properties – reportedly making the pouch compatible with frozen food, bakery products, and confectionary.

The final pouches were then produced at Pack Company. Apparently, they are safe for food contact and recyclable in existing fibre recycling streams.

UPM claims that its UPM Asendo, UPM Asendo Pro, UPM Solide Lucent, and UPM Prego barrier and barrier base papers could all be used in further coatings to enhance each pack’s protective properties and add heat- or cold-sealing.

“The smooth collaboration between UPM, Koenig & Bauer Digital & Webfed and Henkel ensures that the project runs efficiently and effectively, leveraging the strengths of each party and showcasing the latest advancements in digital printing and sustainable packaging solutions,” explains Aleksi Pekkanen, senior researcher at UPM R&D. “The materials used in the doypack pouches are designed to run seamlessly across different processes, ensuring high runnability and consistent quality.”

“We have used UPM paper on our packaging line a few times,” adds Jaana Hakkarainen, director of Sales and Production at Pack Company. “Now that we’ve learned to run heat-sealable barrier papers, it works just like other commercial materials.

“The packaging machines are made for plastic, but we can already achieve the same running speeds with UPM barrier papers. Papers also drive better than plastic and reduce waste because plastic stretches. Paper offers a higher level of dimensional stability.”

Samples of the new doypack will be available at FACHPACK 2024, both from UPM Specialty Papers at Stand 241, Hall 3A; and Koenig & Bauer at Stand 539, Hall 7.

The announcement comes after UPM Specialty Papers revealed the lineup of fibre-based, recyclable packaging papers it will display at FACHPACK this year. These include three solutions, such as a high-barrier concept with oxygen and moisture barriers and water-based coatings, developed in partnership with Michelman.

At the same event, Henkel will showcase its new ‘anti-slip’ palletizing and end-of-life adhesives, developed in line with the Packaging and Packaging Waste Regulation’s requirement that certain industrial and commercial packaging is 100% reusable.

Alongside its own contribution at FACHPACK, Wipak underlines that its easy-open, mono-material doypack for SMUG’s grated cheese – said to offer a 20% reduction in carbon footprint compared to conventional grated cheese packs on the market – has been shortlisted in the UK Packaging Awards.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet