Henkel Adhesive Technologies has partnered with Panverta to create films with an improved oxygen barrier layer, said to reduce the number of layers in dry foods packaging.

The companies state that dry foods packaging must be airtight, light-proof and moisture-proof, but high-quality packaging solutions that meet these requirements usually consist of several layers of different materials, which are often difficult to recycle as they cannot be easily separated.

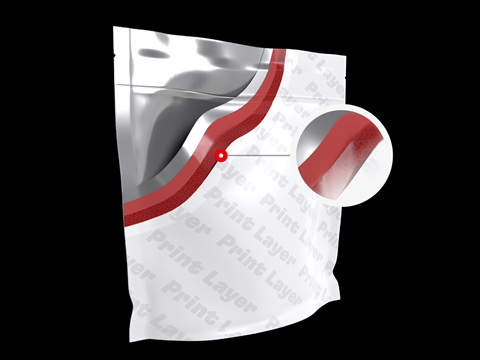

Henkel says its cooperation with Panverta has provided a solution which improves the oxygen barrier performance of metallized cast polypropylene (CPP) to less than 0.5 cc/m2.day and CPP with aluminum oxide coating (AIOx) films to less than 8 cc/m2.day. It adds that the new packaging ensures that the oxygen barrier properties for dry food packaging can be achieved when switching from multi-material designs to mono-material polypropylene (PP).

Henkel’s recyclable Loctite Liofol oxygen barrier coating is being used for the new packaging, which it says is certified recyclable by cyclos-HTP and recognized by the Association of Plastic Recyclers (APR) as meeting the Critical Guidance Protocol for PE films and flexible packaging. According to Henkel, the oxygen barrier layer can be applied to OPP (oriented polypropylene) and PE (polyethylene) films at high machine speeds in excess of 150 to 200 meters per minute and a weight of less than 1 g/m² in both flexo and gravure printing processes.

The solution is due to be presented at Tokyo Pack, Japan, from October 23rd-25th at Henkel’s booth, 1C17, in the form of standing pouches and laminated reels.

Henkel recently teamed up with UPM Specialty Papers and Koenig & Bauer on a heat-sealable ’doypack’ confectionary pouch, aiming to bring together recyclability, high barrier properties, and suitability for both traditional and digital printing methods. The pouches are said to be safe for food contact and recyclable in existing fibre recycling streams.

In September Welton, Bibby & Baron announced it was converting Mondi’s thinnest barrier paper into premium bags for pre-packed fresh bread products, designed to be recycled at kerbside once emptied. The paper reportedly provides the necessary strength for higher filling weights while protecting foods against water vapour, grease, and moisture.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet