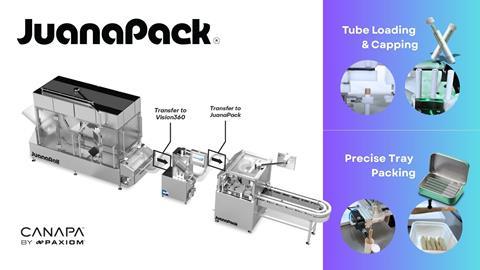

Canapa by Paxiom has unveiled JuanaPack, an end-of-line solution designed to quickly, precisely, and flexibly load tubes and pack trays of cannabis pre-rolls in a single, unified platform.

JuanaPack is described as Canapa’s ‘most advanced and versatile’ end-of-line automation system for pre-rolls, suiting inline, batch-style, or hybrid operations. It encompasses the conveying and loading of pre-rolls for automated tube filling, capping, and robotic tray loading in a bid to boost efficiency and ‘significantly’ reduce labour requirements.

Pre-rolls are loaded directly into tubes and trays; the system is designed to handle products carefully, thus preventing damage and maintaining consistent, clean presentation in every pack. It supports both inline automation and batch-style loading with what is described as ‘seamless’ integration.

Various tray styles can be packed, with upright, inverted, and staggered orientations among the customizable pack patterns on offer. Multipack formats and high-speed tray loading upgrades are also possible, Canapa explains.

To customize workflow integration, JuanaPack can operate alongside the JuanaRoll pre-roll machine, Vision360 inspection, and WeightCheQ checkweigher. KnockBox devices or bulk-fed conveyors can be used for manual pre-roll input.

Additionally, tubes with slide caps, screw caps, and pop tops are expected to benefit from an automated capping process. The system can be paired with Canapa’s tube labelling system to unlock a ‘fully retail-ready’ product.

JuanaPack is recommended to start-ups and high-volume producers alike; Canapa anticipates that the system will cut down on labour costs, eliminate bottlenecks, and help producers keep up with increasing demand.

“JuanaPack is the single solution that cannabis producers need to automate their pre-roll packaging from start to finish,” said Nicholas Taraborelli, vice president, Global Commercial at Paxiom. “It’s powerful, flexible, and built to adapt—whether you’re automating your entire line or enhancing your manual process.”

Elsewhere in the cannabis sector, Contempo Specialty Packaging has unveiled FSC-certified or recycled paperboard versions of its certified child-resistant and plastic-free cigarette box for cannabis pre-rolls. Either option is described as ‘easily recyclable’ at end-of-life and aims to balance safety with sustainability and familiarity.

Meanwhile, Syntegon will present the Syntegon FGCT count feeder, its new handling solution for cookie packaging, at next month’s iba trade fair in Düsseldorf. Cookies are sandwiched together in the desired quantity, then gently but quickly placed on-edge in trays or directly into the infeed of a flow wrapping machine.

If you liked this story, you might also enjoy:

Reuse vs. single use – which is better for the environment?

Sustainable Innovation Report 2025: Current trends and future priorities

What can the world learn from South Korea’s world-leading performance in plastics circularity?

No comments yet