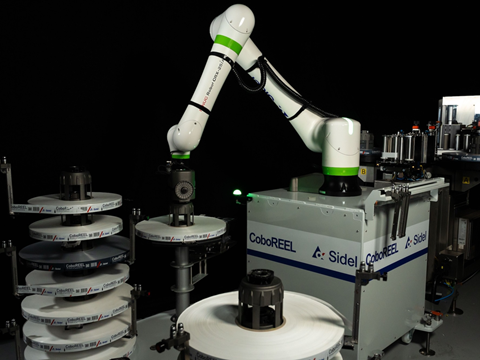

Sidel’s CoboREEL, an automated reel loading solution for beverage packaging labels, utilizes cobots in a bid to triple the reel capacity of other solutions on the market and bolster production efficiency.

Global demand for packaged water is expected to reach over 350 billion litres by 2029, marking a 3.5% increase. Despite increasing regulatory crackdowns in single-use plastics in many countries, the continual rise is said to be driven by increasing tourism, a boom in on-the-go consumption, and the rising scarcity of clean drinking water in several global regions.

Many beverage categories typically packaged in PET are set to grow, Sidel asserts; these include carbonates, driven by health and sustainability trends, with volumes set to upscale by 2.2% by 2029.

In response, CoboREEL aspires to offer the ‘highest reel capacity on the market’ with 18-reel autonomy for a range of different label types and designs – thus intending to meet the demands of such high-volume segments.

By integrating cobots to handle repetitive tasks, such as manual label reel changes, CoboREEL is designed to negate the need for operator intervention throughout the shift duration. Employees can feed the machine at the start of their shift, then focus on other tasks and, according to Sidel, boost overall efficiency and productivity.

It is also anticipated to lessen the risk of manual errors, uploading delays, and misplacements, therefore keeping downtime at a minimum. In the event of a temporary stop, operators can keep loading reels for the next cycle. This is set to boost efficiency, profitability, and return on investment.

Apparently, CoboREEL is intuitive and easy to use. It is not thought to require excessive amounts of technical expertise, nor is it expected to require much maintenance; in turn, it aims to lower the total cost of ownership and accommodate frequent staff turnover.

The system can also function as a standalone unit, working independently from the production line. It can be moved and deployed across different modules as required, as well as interchanged among labellers, for improved flexibility and efficient use of equipment across the plant.

Sidel also emphasizes the system’s ‘unique’ and ‘safety-first’ cobot design, alongside its embedded traceability and <0.5 kWh energy consumption – features implemented to help manufacturers lower their environmental footprint.

“Our customers are looking for ways to work smarter, with fewer resources and in a more efficient and intelligent way,” says Antonio Mancino, product manager – Labelling at Sidel. “Thanks to our five decades of packaging expertise at Sidel, we are constantly developing easy-to-use solutions that reduce costs, speed up daily operations, and require minimal training.

“With CoboREEL, automating reel uploading not only frees workers from repetitive tasks but also allows them to focus on value-added activities where their input is critical.

“With an unmatched reel autonomy of up to 18 reels, Sidel’s CoboREEL sets a new standard in the industry. As the beverage market grows, Sidel will continue to innovate and offer new packaging technologies and solutions that guarantee accuracy, optimize efficiency, boost productivity and increase profitability for our customers.”

This development comes after Sidel unveiled the EvoFILL Can Compact filling solution, which claims to fill up to 40,000 cans of beer, carbonated soft drinks, and other premium beverages every hour – and to provide both flexibility and space efficiency for the low-to-medium speed production market.

Another development in the automation space was recently announced by WeighPack Systems. Its VersaPak vertical form fill and seal bagging machine – also designed for applications requiring automatic loading and flexibility, as well as short runs – is now compatible with paper film, which is hoped to help manufacturers meet consumer demand for environmentally conscious packaging solutions.

Greiner Packaging and Orthomol have also sought to improve both production capacity and product quality for nutritional supplement vials containing recycled PET with the launch of a fully automated production line. Described as the ‘only one of its kind’ in Europe, the line’s Its laminar flow system keeps dust particles away from the vials as they undergo inspection, while its ‘cutting-edge’ camera technology examines their geometry, colour, and possible inclusions.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet