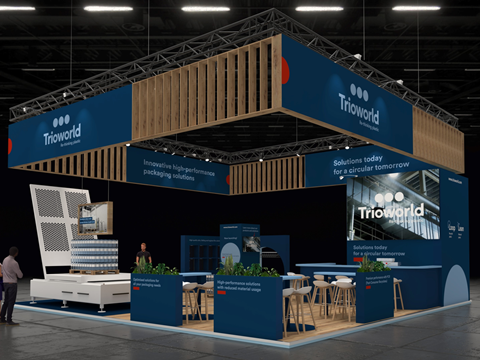

Trioworld will attend FACHPACK 2024 with a new method of separating composite packaging to recover valuable secondary raw materials, alongside a stretch film containing 70% post-consumer recyclate, wet wipe packaging made from recycled beverage cartons, and more.

Following its acquisition of Wentus earlier this year, Trioworld has set its sights on expanding its product offerings in the food and consumer packaging spaces. By the time FACHPACK takes place on 24th – 26th September 2024, it will officially have changed its name to Trioworld Höxter GmbH.

Prior to the combination, Wentus has partnered with Saperatec to separate composite packaging in the recycling stream and recover clean secondary raw materials; this is set to produce pure, adhesion-free post-consumer polyethylene.

Wentus intends to support the development phase by extruding the recovered material. According to Trioworld, this process will make the merged company ‘well prepared for the requirements of the future EU Packaging and Packaging Waste Regulation’.

Saperatec started to build a recycling plant for its composite packaging delamination technology in Germany back in 2022. A pack manufactured using this process has since been awarded a German Packaging Award by the German Packaging Institute; it is expected to package cleaning cloths, although the process is still a prototype.

A fellow German Packaging Awards winner, this time under the Sustainability category, will be showcased at FACHPACK by Trioworld Höxter. New plastic packaging for wet wipes, made from recycled beverage cartons and 35% post-consumer LDPE, is said to be the first pack in Germany to be produced with film plastic sourced from beverage carton recycling.

As a mono-material, it is designed for recycling and is thought to be fully recyclable via existing waste collection systems.

It will also display products under its WENTOPRO brand, including the SkinTight range of premium skin films for fresh meat, fish, poultry, and other products. These are designed to be manufactured with less plastic under lower processing temperatures, thus consuming lower amounts of energy.

Its Trioworld Loop film alternatives are designed to match the film consumption and cost efficiency of conventional solutions while enabling consumers to make the switch to solutions containing post-consumer recyclate. For example, its Katan-Ex Loop30 high-performance stretch film is said to constitute 30% PCR – yet the new Stretch Hood Loop70 is said to contain 70% PCR.

Reportedly, the higher percentage of PCR does not have a negative impact on the stretchability and holding force of a virgin stretch hood solution. Instead, Trioworld says it offers a ‘particularly economical use of material’, as well as ‘outstanding’ load stability and, therefore, increased transport safety for covered pallets.

Both Katan-Ex Loop30 and Stretch Hood Loop70 intend to help customers lower their packaging-related carbon footprints compared to virgin material.

Other companies presenting at FACHPACK include BEUMER Group with its ‘maintenance-friendly’ stretch hood technology. This can be used with films containing recycled content and claims to improve safety, efficiency, and ergonomic performance.

UPM Specialty Papers will also bring its fibre-based, recyclable packaging paper range, including solutions co-created with customers and partners across the packaging value network. For example, its work with Michelman has resulted in a high-barrier concept with oxygen and moisture barriers and water-based coatings, designed to provide a new option for end-uses such as chocolate.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet