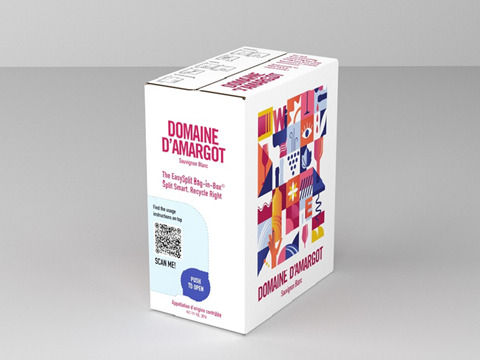

Smurfit Westrock aims to adhere to the Packaging and Packaging Waste Regulation’s minimum requirement of 80% recyclability with its EasySplit Bag-in-Box design, which claims to streamline the separation of the plastic bag and cardboard box components.

Bag-in-box packaging is designed to be easily separable, enabling its components to be recycled in their respective streams. Doing so it set to increase the pack’s overall recyclability rate to over 90%.

However, this relies on the feasibility of separating the bag from the box. If consumers resort to disposing of the whole pack together, it will be processed in the dominant material’s recycling stream, which is usually cardboard.

Since the bag component cannot be recycled with cardboard, it could limit the pack’s recyclability rate at 75%, and could potentially fall lower if the plastic bag impacts the paper recycling process.

Smurfit Westrock is unveiling its patented EasySplit Bag-in-Box design in response. Apparently, the pack ‘significantly enhances the ease’ of bag and box separation, thus improving recyclability and helping users comply with upcoming regulation.

“With the European Commission set to decide on the methodology within the next three years, it is imperative to act swiftly and demonstrate a viable solution to the challenge,” said Massimiliano Bianchi, CEO of Smurfit Westrock Bag-in-Box. “Smurfit Westrock is leading the charge in preparing the packaging industry for future regulations by launching our EasySplit Bag-in-Box design.

“As we continue to educate consumers and stakeholders about the importance of proper recycling practices, Smurfit Westrock remains dedicated to driving positive change and demonstrating environmental stewardship.”

In other news, Alesayi Beverage Corporation is making use of SIG’s bags, fitments, and filling system to provide bag-in-box packaging to hotels, restaurants, and cafes. This will involve the use of 10L bags made from one-layer SIG 2Pure Film for bag-in-box applications; the SIG OptiTap 2300 self-closing thumb toggle valve; and SIG’s SureFill 42 Aseptic BIB filling line.

Smurfit Kappa has also invested €54 million into its Ibi Bag-in-Box facility in Alicante. This move was expected to double the plant’s capacity, lead to ‘significant’ reductions in energy consumption, and improve the general sustainability of Smurfit Kappa’s product portfolio.

More recently, the merged Smurfit Westrock company has collaborated to redesign packaging for various products, from ‘shelf-ready’ beer boxes for Woodforde’s to bespoke printed postal boxes for Poppin Candy. Both are intended to catch a consumer’s eye – on supermarket shelves and social media, respectively.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet