drinktec 2025 will be bringing beverage and liquid professionals together in Munich from the 15th -19th September 2025, and Packaging Europe will be on the ground reporting on the key moments.

In this article, we’ll be keeping you up to date with all the Drinktec-related news, comment, and updates you need to know about.

drinktec 2025 will open its doors on September 15th. Around 1,100 exhibitors will present solutions and future technologies in eleven halls at the Munich Exhibition Center.

They will once again be dialogue partners for all national and international decision-makers when it comes to investment decisions and the strategic orientation of brands. This exchange will be based on a complete overview of all raw materials, process technologies, filling and packaging technology, logistics, and IT directly at drinktec, where all projects with the experts can be discussed.

With a comprehensive range of products covering the entire value chain of beverage and liquid food production, visitors to drinktec will gain inspiration for the future orientation of their product portfolios and learn about the latest trends in the industry.

New Liquidrome – Hotspot for knowledge transfer and networking

The new “Liquidrome” format provides additional impetus. Under this branding, the trade fair team in Hall C4 is presenting a wide-ranging supporting programme: exhibitor talks, presentations on research projects, and practical insights form the backdrop for strategic decisions in visitors’ own market and brand scenarios. In this environment, numerous start-ups will also be showcasing new solutions and answering critical questions from the audience during start-up pitches.

All offerings in Liquidrome focus on the key topics of “Circularity & Resource Management,” “Data2Value,” and “Lifestyle & Health.” “Here on our large Wave Stage, we have a diverse programme that includes macro trends, AI solutions for practical use, and numerous ideas for resource-efficient production,” emphasizes Markus Kosak, Executive Director of the drinktec Cluster. With several offerings on innovation strategies and insights from the start-up scene, the Deep Dive Lounge in the Liquidrome complements the programme and offers ample space for networking.

Pathways to lower emissions and full circularity in aluminium packaging

At drinktec 2025, Ball showcased circular aluminium packaging solutions from cans to bottles as well as focusing on consumer experience, design and personalization. At the event, Elisabeth Skoda spoke to Dr Mandy Glew, President, Beverage Packaging EMEA, discussing carbon emissions, sourcing, circularity, regulation, innovation perspectives for packaging and more.

Click here to read the full article.

Things to see:

High-speed shrink sleeve application with Fuji Seal

On the final day of drinktec 2025, Nicolas Gallardo presents Fuji Seal’s high-speed shrink sleeve label machine, partial label applicator, HS Tunnel system for sleeve applications, and more – all catered towards customers in the dairy, beverage and food sectors.

Mono-materials, tamper evidence, and more with Aptar Closures

Next up in our drinktec series is Aptar Closures! Nicola Maffi runs us through the sports beverage closures on display – Rocket GME 30.40, Balance 30.40, and NexTE 29.25 – and their benefits for one-handed opening, tamper evidence, ease of recycling, and more.

Husky Technologies balances sustainability and profitability

Live on the ground, Haim Za’afrani presents Husky Technologies’ 200-cavity molding system, PET closure forming technology, and the launch of its Advantage+Enterprise solution as the company targets both sustainability with profitability.

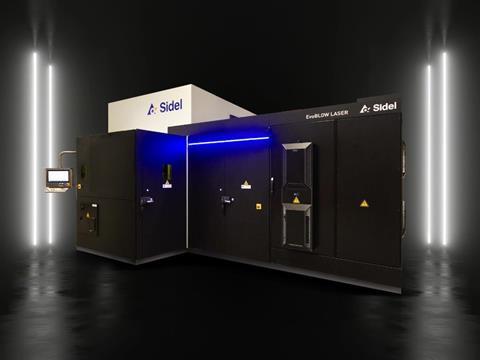

Sidel launches laser technology solution for food and beverage packaging

Sidel has revealed plans to launch its EvoBLOW Laser at drinktec 2025, aiming to ‘redefine’ lightweighting for PET and rPET in the food and beverage industry, said to reduce preform waste by 50%.

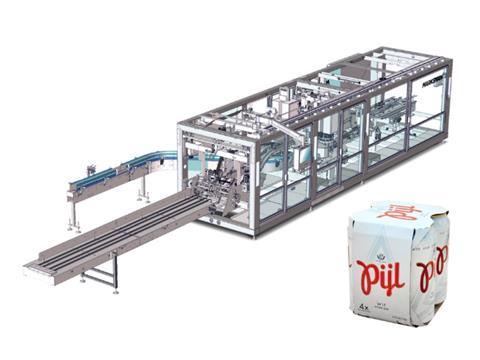

Graphic Packaging debuts beverage multipack innovations

Graphic Packaging Internationa l has unveiled two first-to-market innovations at drinktec 2025, which the company says are offering beverage brands and producers new ways to drive premium shelf presence, eliminate shrink film, and maximise operational efficiency.

The two innovations — wrap-style paperboard multipacks with primary container orientation and a modular multipack system for shrink film replacement on tertiary packaging, including clip-style solutions — are being demonstrated at the Graphic Packaging booth, Hall C1, C1-321.

This latest design of wrap-style multipacks ensures that the orientation of the primary container is consistently maintained through the supply chain and onto the retail shelf, enhancing on-shelf impact by ensuring every can faces the same direction and also eliminating the need for a separate ad panel to cover barcodes. This reportedly cuts paperboard volume by approximately 25% compared to wraps with an ad panel, supporting material minimisation goals.

Designed to run on a customer’s existing high-speed Marksman™ machine, the new wraps with orientation deliver excellent operational efficiency, do not compromise speed or machine footprint, and are ISTA 3E certified, providing assurance that they will meet tough supply chain demands.

Also debuting at drinktec 2025 is a new family of multipack modules designed to replace shrink-film on corrugated trays used for tertiary packaging or distribution. The modules can add paperboard clips (EnviroClip™ or EnviroTop™) to loose bottles and cans or can place paperboard multipacks directly into trays. The modules are reportedly fast, flexible, and compatible with a wide range of primary containers and pack configurations. They can be installed behind any current tray packer equipment, or with Graphic Packaging’s new QuikFlex™ TP tray packer, which is built on proven QuikFlex technology and can run both corrugated and paperboard trays.

“There’s a lot of talk in the industry about future-ready packaging, but what brands really need are solutions that work right here and now — on their lines, in their supply chains, and on the shelf,”said Steve Gould, director of new business development, global beverage, at Graphic Packaging. “

Ardagh Group showcases metal and glass packaging

Ardagh will present its latest innovations and product developments at drinktec. Both Ardagh Metal Packaging (AMP) and Ardagh Glass Packaging (AGP) will be represented at the event, highlighting their expertise in delivering high-quality, sustainable packaging solutions for the packaging industry. Together, they will showcase a wide range of innovative products, formats and technologies designed to support brand differentiation, consumer convenience and circularity.

AMP will present its full standard range of beverage cans and ends, with a specific focus on their— the “Five Times Unique” product range: H!GHEND, Wine Cans, Embossed Cans, Nitro Cans, and digital can printing in partnership with NOMOQ. The company says that each of these products offers distinct benefits for beverage brands looking to enhance visual impact, improve functionality, or explore new trends and consumer behaviours.

The AGP-Europe team will present its latest glass container designs alongside its most recent global innovations, offering visitors a first-hand look at how the company is shaping glass packaging worldwide. The team will also share updates on the broad range of sustainability projects across the region via an interactive map. The stand will also feature a display of lightweight wine bottles in a variety of colours and styles that combine elegance and strength with a reduced environmental impact.

Ardagh Group invites visitors to experience its packaging solutions first-hand and explore how metal and glass can elevate brands in a changing market.

Join Ardagh at drinktec 2025 in Hall C2, Stand 140.

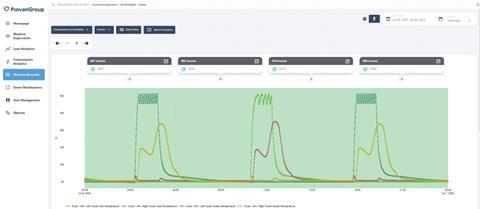

PiovanGroup launches SmartForesight and AryaDew

Unplanned equipment failures cost manufacturers millions annually. Production lines stop, deadlines slip, and profits evaporate when critical dryers fail without warning.

SmartForesight is reported to transforms maintenance from reactive to predictive. PiovanGroup’s intelligent monitoring solution provides predictive analysis of GN, GP, and GMP dryers, detecting abnormal behaviour before the fault occurs. Cloud-based edge technology delivers real-time alerts directly to Piovan Service team and yours. The system’s customizable monitoring capabilities allow both predictive control and precise monitoring to be tailored to specific customer requirements to meet various customer needs and operational realities.

Maximize uptime, prevent costly breakdowns, and optimize ROI through proactive maintenance scheduling. IEC 62443-3-3 cybersecurity compliance ensures data. Monthly performance reports and direct access to Piovan experts accelerate operational improvements.

SmartForesight is described as integrating seamlessly with existing systems and also features extended warranties, priority field service and comprehensive training programs.

Also at drinktec, PiovanGroup will present AryaDew, an energy-efficient dehumidification solution that the company says delivers 70% cost savings.

Rising energy costs plague plastic manufacturers worldwide, impacting profitability while demanding consistent production quality.

AryaDew by Thermal Care revolutionizes mould cabin dehumidification through closed-loop cooling cycle technology. This system delivers up to 70% energy savings compared to conventional solutions, ensuring constant dew point control for optimal production environments.

With a reported payback periods under two years, AryaDew is designed for PET preform production, high-speed injection molding, blow moulding, and injection blow moulding, the system prevents mould condensation while optimizing production cycles. Smart Adaptive Fans (SAF) technology maintains consistent performance through variable-speed, high-pressure ventilation.

Industry 4.0 compatibility enables seamless integration into existing production systems without water pre-cooling requirements. Simplified installation reduces operational costs while minimal maintenance maximizes uptime.

Visit PiovanGroup at drinktec at booth C6-380.

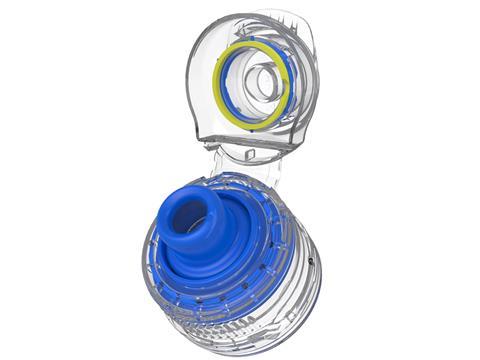

Tamper-evident, recycling-ready sports beverage closures by Aptar

Aptar Closures will showcase its latest generation of sports beverage closures at drinktec: NexTE, Rocket, and Balance.

Designed to align with Europe’s Packaging and Packaging Waste Regulation (PPWR) and Single-Use Plastics (SUP) directive, Aptar says that its Closures solutions help brands stay compliant while delivering the elevated performance today’s consumers expect.

With a streamlined design and integrated latching tamper evidence, NexTE Sport Closure seeks to provide a familiar and intuitive one-handed opening experience while enhancing consumer safety.

The closure features a visible, non-detachable tamper evidence band that flexes back for a comfortable lid opening motion. NexTE is suitable for both ambient and dry aseptic fill applications.

The three-piece Rocket Sport Closure features a wide, comfortable opening enabled by advanced hinge technology that reportedly eliminates spring-back and enhances drinkability.

Its visible, non-removable tamper-evident band clearly indicates if the product has been opened, with the aim of providing added security for consumers.

Aptar says that Rocket is also optimized for recyclability and supports both ambient and dry aseptic fill applications.

The closure enables the transition to a lighter neck finish (GME 30.40), apparently allowing brands to reduce bottle weight without compromising the drinking experience.

The new Balance Sport Closure is a lightweight, mono-material (polypropylene) solution that also supports the transition to a lighter neck finish.

Balance offers one-handed operation, a reassuring “click” upon closure, and an audible, tactile, and visible tamper-evidence system that aims to provide added assurance for both brands and consumers.

All of the above can be seen in Hall C6, Stand C6-342.

Beverage coding innovations by Domino

Domino Printing Sciences will be at drinktec 2025 to introduce beverage packaging solutions that it says will deliver greater efficiency, traceability, and sustainability.

Visitors can take a look at Domino’s latest coding solutions for beverage manufacturing, including high-speed laser systems, smart 2D code integration, as well as its advanced, all-in-one, can coding system.

Highlights include Domino’s Dx-Series CO₂ lasers, labelless PET bottle coding using a Dx-Series blue tube variant, the new 100-watt Dx1060i for glass coding, F-Series fibre lasers for coding on canned beverages, and the company’s new Beverage Empty Can Coding System (BECCS).

You can visit Domino at booth A5-101.

No comments yet