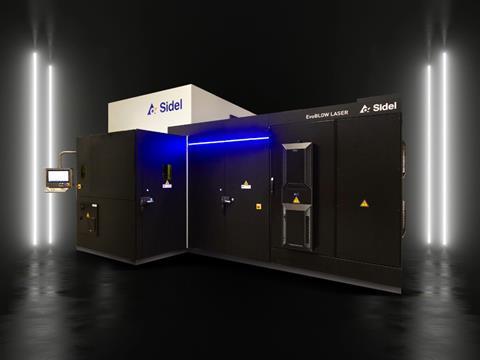

Sidel has revealed plans to launch its EvoBLOW Laser at drinktec 2025, aiming to ‘redefine’ lightweighting for PET and rPET in the food and beverage industry, said to reduce preform waste by 50%.

Sidel says that the technology reduces preform waste by 50% compared to traditional solutions while benefitting from a smaller oven, measured on the EvoBLOW Laser solution vs Sidel’s comparable halogen-based solution.

The EvoBLOW Laser utilises up to 36 heating lines, seeking to provide control over the material’s thickness along the entire container. It is also said to enable lightweighting even for premium bottles, thanks to the creation of small rings of thicker material invisible to the consumer. These rings make the bottle feel and act stronger while using less overall material.

The laser technology is said to make lightweighting possible in previously inaccessible areas such as beneath the bottle’s neck and require only one process setting per heating line (intensity). This stability ‘guarantees’ that every preform receives the precise thermal profile needed, consistently delivering the desired result regardless of ambient temperature changes.

According to the company, the EvoBLOW Laser eliminates downtime at every stop and start, with no ‘stand-by’ mode required to keep the oven warm. Live speed modulation is said to improve efficiency, as the blower can automatically and temporarily adjust its speed in real-time to meet changing conditions or circumstances on the line. The cold oven technology also allows fast access to the oven without waiting for cooling, with zero risk of burns.

In related news, Videojet Technologies unveiled its 7920 UV laser marking system last year, aiming to boost ease-of-use, flexibility and reliability in coding operations for the consumer packaged goods, parts marking and pharmaceutical industries. To simplify product changeovers and help with consistent code clarity, it has multi-level surface marking, an auto-adjustable focal distance, uniform flat field correction and a pilot beam focus finder.

Domino Printing Sciences introduced its K300 piezo inkjet printer and Dx-Series range of CO2 laser coders recently, aimed at providing life sciences manufacturers with end-to-end solutions for advanced variable data printing, including 2D codes at the individual dose and item level. The new printer is designed for applications on blister foils, flexible films, medical papers and single-dose blow-fill-seal ampoules and vials.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet