Fortress Technology has announced plans to debut its Vyper Vision automated top and bottom label inspection solution at PPMA 2025, aiming to ensure compliance with retailer food safety and labelling requirements.

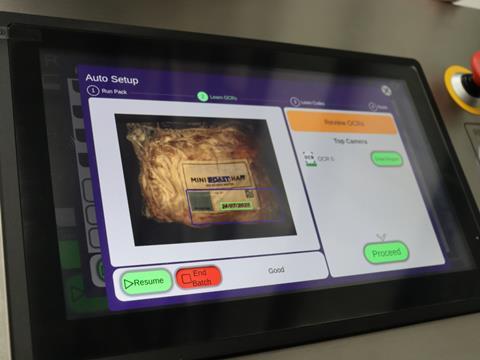

Vyper Vision is said to give food processors a ‘high-speed, easy-to-integrate’ system for inspecting label application and placement, use by dates, allergens, ingredients, batch numbers and barcodes, examining every label on every pack at 200ppm. Seeking to prevent label-related defects reaching the point of sale due to wrong data input, poor quality printing or illegible allergen details and barcodes, Vyper Vision aims to safeguard consumers and prevent the issuing of food safety alerts and recalls.

Fortress Technology plans to demonstrate the new system on a Raptor Combination metal detector and checkweigher within the same footprint. Vyper Vision uses advanced optical character recognition (OCR) to detect and reject faulty labels, printing errors and poor-quality print in real time.

The company adds that OCR adjusts to variable lighting conditions and variations in font sizes and label distortions, as well as adjusting automatically to different packaging types. The camera is IP65-rated and is within a waterproof enclosure.

Suitable for industrial food manufacturing environments, out of tolerance packs are instantly rejected into a lockable bin, with every reason for rejection automatically captured as an image and sent as a digital file to a processors central network, where it can be stored electronically.

Designed to be compatible with any Fortress inspection system, Vyper Vision can be connected to a customer’s centralised data and reporting system utilising various communication adaptors such as OPC UA. It can also be programmed to inspect special promotional labels and 2D and 1D barcodes, as well as special cooking and storage instructions.

In related news, Antares Vision Group collaborated with Oròbix to create an AI-driven visual inspection platform developed to meet growing needs for faster, more accurate and adaptable inspection processes. AI-GO can consistently identify complex anomalies such as chromatic impurities, glass fragments, cosmetic defects or foreign bodies, said to result in a reduction in false rejects.

Last month Canapa Solutions by Paxiom announced its Vision360 automated inspection system specifically for pre-rolls, said to reduce manual labour and improve throughput. The system provides real-time inspection of a pre-roll’s filter, body, and twist, designed to automatically detect flaws including colour, irregular lengths, tears, cuts, depth inconsistencies, and other imperfections.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet