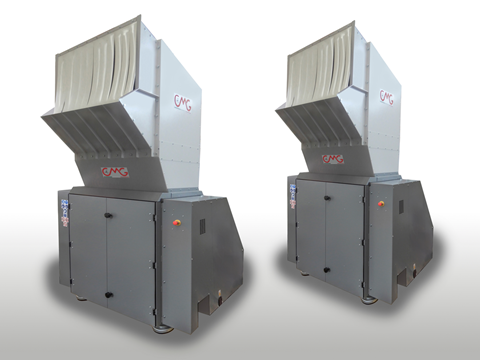

CMG Granulators has introduced its new G55 granulator line for high-capacity applications, aiming for high productivity, efficiency and improved accessibility for cleaning and maintenance.

The new G55 Line consists of the G55-90 and G55-120 models, and the standard configurations of the new series cover capacities starting from 700 kg/h to 1.300 kg/h. CMG says the line has integral sound enclosure and a feed hopper designed to accommodate a variety of shapes and dimensions.

All models are said to operate in high-efficiency conditions and are equipped with EISA premium-efficiency motors and can have AMP controls (Adaptive Motor Power). According to CMG, the cutting chamber in the new line is assembled from CNC machined steel parts with tolerances down to the hundredth of a millimeter, aiming to guarantee an accurate cut and no generation of dust. In addition, the high fabrication precision reduces friction and abrasion and no cooling water is necessary.

The regrind is evacuated from the granulator collection bin by CMG’s proprietary full vacuum regrind conveying system. All cleaning operations and maintenance needs can be fulfilled by accessing the unit from the front and the back, and the cleaning does not require tools.

The new G55 line is equipped with controls monitoring all functions of the granulator unit and all ancillary elements, from the moment the part to recycle is placed on the infeed conveyor up to when the regrind is conveyed into a surge bin for subsequent utilization, or into a bag for transportation to other locations. CMG Granulators states its solutions are certified for compliance with Industry 4.0 and respond to the pre-requisites necessary to fulfil 5.0 requirements.

Systech introduced its ST16 Semi-Automated Multi-Aggregation Station for pharmaceutical manufacturers, CMOs, CDMOs, re-packagers and distributors last month. Aiming to optimize productivity and improve efficiency, the system provides a case label printer and an optional pallet label printer, as well as the option for pallet label inspection.

Also in January, WeighPack Systems announced the release of its Swifty Bagger S-3600 Duplex Servo machine for pouch bagging, designed to maximize productivity, flexibility and ease of use. DTM Print recently launched its new LX4000e Color Label Printer, seeking faster processing, reduced downtime and maximum productivity.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet