Andy Zosel, President and Chief Executive Officer at OMRON Microscan, and Kenta Yamakawa, Senior Vice President at OMRON Microscan, explore the different iterations of traceability and how it can help to optimise productivity, quality and brand reputation.

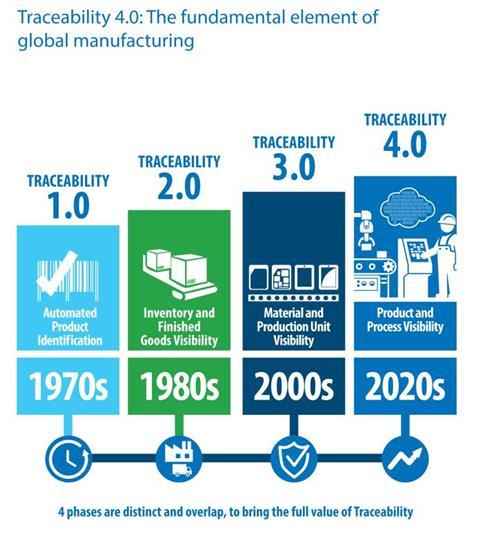

The breadth and scope of traceability has expanded significantly over the years along with advances in technology, making it a ubiquitous and critical application for today’s world-class manufacturers. Traceability is a much-used term these days in manufacturing and supply chain management. Like many industry phrases (Internet of Things, for example), traceability can mean different things to different people or organisations.

For that reason, “Traceability 4.0” is the term that Omron has coined to describe the current and future phases of traceability in a global context. This article will explore the evolution of traceability and its nuances and explain why the latest phase of traceability is not just about tracking products and components throughout the supply chain, but also optimising productivity, quality and brand reputation within the manufacturing operation by tying product to process parameters.

Traceability 1.0: Product visibility

Traceability 1.0 is about automatically identifying products to drive accuracy and efficiency. Barcode readers were initially used in simple manufacturing processes, yet grew rapidly in adoption. Barcodes became, and still are, a necessary core in manufacturing and industry to improve operator efficiency and productivity. In manufacturing, this is quite often the “first step” in implementing traceability solutions.

The barcode’s first grand-scale commercial use was in retail operations. Prior to the advent of barcodes, cashiers had to key the product and price into a cash register. The automatic data capture enabled by barcodes saved a significant amount of time, improved accuracy and increased throughput. Developed for retail, the first Universal Product Code (UPC) debuted in 1974 and they are still in use today.

Another adaptation of bar code use, still prominent today, is the use of 1D barcodes on test tubes containing animal or human specimens. Barcodes are used to track individual specimens and to ensure that test results are associated with the appropriate specimen and patient. Today, there are many more widespread applications in use.

Traceability 2.0: Supply chain visibility

Traceability 2.0 is about managing inventory and meeting the needs of society. Now that barcodes were being applied to manufactured items, manufacturers recognised additional uses for them. Comprehensive tracking, from original raw materials to finished products for the purpose of optimising inventory management and reducing cost, became possible. At the same time, consumers became more quality- and health-conscious, and the media became more aggressive in responding to product quality issues.

Whether a supplier, manufacturer or consumer, no one wants to be involved in a product recall due to the issues and costs it can cause. The demand for Traceability 2.0 has skyrocketed, largely to address this issue and broader social needs and awareness. Traceability 2.0 enables targeted product recalls according to date and lot codes. This reduces the cost of quality improvement and also increases consumer confidence, as manufacturers can now pinpoint the source of the problem within their processes.

Retailers push traceability requirements onto manufacturers and require that barcodes themselves have high standards of quality. The retail industry, as well as the United States Food and Drug Administration (FDA) for the manufacturing of medical devices (Unique Device Identifiers or UDI), has adopted the International Organization for Standardization (ISO) barcode quality specifications, which impacts multiple levels within the respective supply chains.

Traceability 3.0: Line item visibility

Traceability 3.0 is about the optimisation of manufacturing and supply chain security by focusing on material, the second of “the 4Ms of lean manufacturing”: Man (People), Material, Machine and Method. For this paper, “Material” applies to all that is necessary to build a product: raw material, components and subcomponents, as well as the finished product with serial number. Manufacturers began to extend traceability to their suppliers by requiring barcodes and other identifying information be placed on components and packaging. Some refer to this as component, subcomponent or line item traceability. As more suppliers began adding information, manufacturers were able to optimise manufacturing processes and product quality even further by employing traceability within the manufacturing facility.

Traceability 3.0 is also about the ability to perform preventative control, before an emergency or quality issue occurs. Subcomponents can now each be identified, tracked and inspected for quality before final assembly. When a manufacturer is able to go back to the last acceptable checkpoint, adjustments can be made in final production to assure quality products are released for shipping. The introduction of Data Matrix (developed by a company in Omron’s acquisition genealogy) and other 2D symbology greatly facilitated Traceability 3.0, as symbols could be substantially smaller than their 1D counterparts while containing more data. This is especially important in the electronics industry, where device components continue to decrease in size. The development of the Direct Part Mark (DPM) occurred during this phase of the traceability evolution because of the need for robust identifiers to withstand harsh manufacturing or environments. Manufacturers etch DPM symbols directly onto materials such as metal or plastic, eliminating the need for easily-damaged barcode labels.

Lastly, Traceability 3.0 provides manufacturers with a greater ability to ensure the authenticity of their products and a better foundation for anti-counterfeiting programs. Counterfeit automotive parts are estimated to cost the industry between $10 billion and $30 billion per year. By identifying all of the components in an assembly or product and improving the resilience of 1D barcodes and 2D symbols, manufacturers are able to implement programs that successfully reduce counterfeit products from entering the supply chain.

Traceability 4.0: Process visibility

So far, we have discussed product, component and supply chain tracking as key traceability goals. Traceability 4.0 is the union of all these, along with machine and process parameters to achieve the highest level of manufacturing, including Overall Equipment Effectiveness (OEE). Although some manufacturers are already employing Traceability 4.0, it represents the future for the majority of companies.

A similar way of describing Traceability 4.0 is the complete implementation of traceability in the context of the 4 Ms of lean manufacturing. Manufacturers can now know everything there is to know across their enterprise about a part or product, including its complete genealogy. Traceability 4.0 greatly enhances root cause analysis. On which machine was this product produced and at what time? Who was operating the machine? Where is the production bottleneck located? The potential diagnostic scenarios are virtually limitless.

Substantial improvements come to light in many areas with Traceability 4.0. The ability to identify specific product failures with detailed operating parameters and conditions enables faster and more precise root cause analysis. Manufacturers can also drive manufacturing decisions and processing with this phase. Through what process does a particular part move during production? What route does a part take throughout the manufacturing process? Which components are used on a specific sub-assembly? Assembly verification, quality assurance, and bill of material control are all optimised with Traceability 4.0.

Finally, in an advanced state, Traceability 4.0 systems can make automatic decisions that optimise equipment and processes based on acquired data, including automatic predictive maintenance. This is facilitated by smart sensors, AI controllers, RFID and advanced data management software. This process knowledge can then lead to improvements in other facilities across the enterprise and around the world.

A holistic approach to traceability

All levels of traceability are critical to the success of manufacturing. In fact, most industries will see and use all levels in their plants or facilities. One phase is not “better” than the other; the full complement is their strength. The evolution of traceability is the direct result of business needs and is crucial in the hyper-competitive world of global manufacturing.

While similar in many ways to Industry 4.0, Traceability 4.0, and all its phases, is different in several ways. Timing and availability is one key difference. When speaking of Industry 4.0, in some cases there are decades between advancements, and generally they are not being developed, or used, at the same time. Many steps of this progression were sequential. The concepts and technologies of traceability began just 40 years ago, and are actively building upon each other and are being used concurrently, for both bettering production and sparking new technology developments.

The other large difference we see is the focus of Industry 4.0 compared to that of Traceability 4.0. They both focus on improving and connecting digital and physical technologies to optimise manufacturing and improve yield. Traceability, however, brings an additive dimension – ensuring quality components and end products. It is this laser sharp focus on credibility and brand protection that true traceability can deliver.

Crucially, the four phases of traceability have not cannibalised one another. They have in fact been accretive, and will continue to build upon each other. Transactional efficiency, social needs, supply chain management, and manufacturing optimisation will only become more important in the coming decades.