Announcing the finalists of the Sustainability Awards 2018! The seventeen independent judges for the leading competition for innovation in sustainable packaging have graded all the submissions over the summer – and this week Packaging Europe is revealing the top four entries in each category. The six category winners and overall Sustainability Awards 2018 winner will be unveiled at Scanpack on 23 October.

Here (in alphabetical order) are the four finalists in the ‘Driving the Circular Economy’ category, which was conceived to celebrate breakthroughs and innovations in recycling or reusable packaging systems; initiatives promoting increase in recycling rates or nurturing demand for recyclate:

Finalist A:

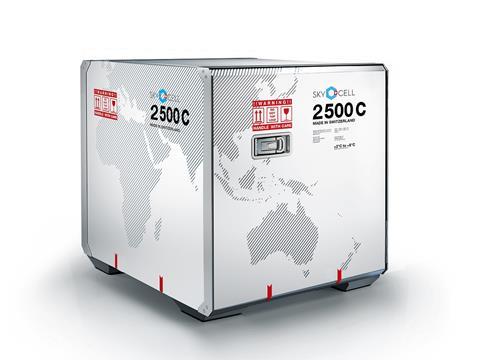

2500C Recycled Plastic Temperature Controlled Container - submitted by SkyCell AG

Overview

SkyCell is a Swiss-based provider of temperature-controlled airfreight container solutions with a special focus on serving global pharma companies and sustainability. It is driven by its mission to supply the safest pharma containers worldwide. This is achieved through a combination of hardware, software and services, which enables SkyCell to master logistical challenges and eliminate temperature excursion.

In mid-2017, SkyCell launched a new model of its temperature-controlled containers, called 2500C. It is the largest container for temperature-controlled transport with passive systems, which makes it much lighter than its competitors. More than 50 man-years of R&D were poured into creating an unprecedented, highly efficient insulation solution. This cutting-edge technology reflects the maximum radiation while minimising heat conduction. It is the most patent-protected insulation technology on the market and made of recycled plastic.

These aspects lead to a drastic reduction of fuel for air transport, and hence C02 emission. In its latest study, the international NGO MyClimate examined the CO2 emissions of SkyCell containers compared to products of competitors. The results show that SkyCell’s 2500C container basically cuts in half the CO2 emissions during examined air transports compared to containers with a similar capacity.

Impact

Since its launch in mid-2017, SkyCell’s model 2500C has convinced many pharmaceutical companies to switch from heavy actively-cooled containers for air transport to SkyCell’s passively-cooled models.

In the past, passive systems were not able to keep the temperature for pharmaceutical shipments inside the container in the required range. So frequently, pharma companies have chosen actively controlled containers in the market, despite the fact that they are much heavier than passive ones and leave a much larger carbon footprint. Since it entered the market, SkyCell has been audited by more than 12 of the biggest 20 pharmaceutical companies and passed all tests with tailwind.

“Pharma companies tested our containers in their climatic test chambers and, at first, did not believe the results. Outside temperatures were changed from plus 60 to minus 30 degrees Celsius, but inside our containers, there was not even a temperature deviation of a single Kelvin. In their traditional mindset, this was regarded as impossible,” says Nico Ros, CTO and co-founder at SkyCell.

The technology saves about six tons of CO2 per shipment and cubic metre of goods. This is the equivalent of a 50,000 km car ride per shipment. Hence, the revolutionary design of SkyCell’s containers will drastically reduce the carbon footprint of airfreight in the years to come.

Finalist B:

Coca-Cola Freestyle with re-usable intelligent bottles - submitted by Whirley-Validfill in collaboration with The Coca-Cola Company

Overview

In 2017 Coca-Cola introduced a re-usable/refillable bottle scheme at the University of Reading in the UK. This scheme operates in combination with the Freestyle dispensers and has ensured removal of all one way-consumer packaging from the campus. This project was developed in collaboration with the bottler, Whirley-Validfill and Reading University, who branded this scheme ‘SUSTAIN IT’.

The refillable bottle contains an RFID-tag at the bottom which is read by the dispenser. The university offers a program whereby students can credit their bottles for a number of refills. The refills can be defined by a set number (for example 10 refills) or by a given period (for example: unlimited refills for a week/a month or a term). In the latter case - in order to control abuse - the equipment will ensure a ‘given waiting time’ between two pours (for examples 10 minutes of waiting before a second drink gets poured).

In addition to the education channel, the combination of the Freestyle dispensers with RFID has potential to be used in leisure parks, festivals and events, hotels and working environments to remove single-use consumer packaging.

Impact

The immediate impact on one university campus is the elimination of 600,000 one-way bottles per year. Spreading this across multiple customers and channels could make this eliminate more than 50 million one-way bottles per year across Europe.

The capability to offer environments a world without consumer waste: a bottle becomes a re-usable asset that has a 'credit' loaded onto it.

The industrial waste (the packaging needed to fill the equipment with ingredients) generated by Coca-Cola Freestyle is 40% lower than in the traditional dispensed beverages business.

Applying this technology within the channels where teenagers and young adults operate recruits this generation into consuming sustainably.

Finalist C:

CupCycling™ - submitted by James Cropper

Overview

The use and disposal of take-out coffee cups is a deeply concerning issue within society, with only a fraction of cups – one in 400 – being disposed of correctly. Consumers’ love of takeaway coffee shows no signs of diminishing, so a solution that reduces its environmental impact is high on the agenda for both the government and industry.

With CupCycling™, James Cropper has developed the technology to recycle disposable paper cups on a commercial scale for the first time, and has played an integral role in establishing demand for paper produced from used cups. By partnering with waste management companies, coffee chains and restaurants, James Cropper has created a suitable supply chain to enable cup waste to be transformed into beautiful papers.

High street restaurants and retailers, such as Costa, McDonald’s, and Selfridges, have installed cup collection stations to allow for correct disposal. There are now more than 4000 dedicated cup recycling stations nationwide. The used cups are collected by waste management partners for processing, before being delivered to James Cropper’s plant.

In a standout example of closed-loop recycling, James Cropper is rescuing Selfridges’ used cups from landfill and turning them into the yellow paper used to make the retailer’s iconic shopping bags. The bags can then be recycled with household paper waste, giving them a new lease of life for years to come.

CupCycling™ is a working example of the circular economy in action and how collaboration between businesses can lead to successful outcomes for both industry and the environment.

Impact

Since it was opened in 2013, the plant has recycled the equivalent of two billion cups’ worth of post-industrial coffee cup trim. Since September 2017, CupCycling™ has recycled more than 20 million used cups, but has the capacity to upcycle 500m cups per year, offering a significant solution to the UK’s coffee cup issue.

With the Selfridges collaboration specifically, James Cropper is saving over 200,000 cups from landfill per year and putting them back into Selfridges’ iconic shopping bags.

A Life Cycle Assessment has shown that whilst there is no overall ‘best fibre source’ that is superior in every environmental category, paper from recycled cup trim and recycled coffee cups generally has a lower environmental impact than fibre sourced from renewable forestry sources or office waste.

Investment in improved infrastructure and consumer education – which James Cropper is working on with the PCRRG (Paper Cup Recycling and Recovery Group) and CPI (Confederation of Paper Industries) – will ensure a more joined-up approach, leading to a greater level of cups being disposed of correctly and given another life.

Following widespread publicity of James Cropper’s solution, new retail partners have been in touch, both those that want to send their used cups to the CupCycling™ facility and those that wish to use the resulting papers in their packaging. Such partnerships will allow for the upcycling of a significant number of disposable coffee cups used each year.

By 2020, CupCycling™ has the potential to have rescued around one billion used cups.

Finalist D:

Pattex Made at Home Universal Glue - submitted by Henkel AG & Co. KGaA

Overview

Together with development partners Borealis / mtm, bomo trendline Technik GmbH and KKT Kaller Kunststoff Technik GmbH, Henkel has managed to successfully develop, qualify and launch its first consumer adhesive packaging which is entirely made of post-consumer recycled resin. Both the extrusion blow moulded bottle and the three-piece injection moulded closure are made from 100% PCR and thus close the first loop of recycling.

Impact

By successfully launching this product it is proved that the use of post-consumer recycled polyolefins can be a technically and financially viable option in mass products and consequently the use of virgin resin can be drastically reduced.

Want to be the first to know the winners of the Sustainability Awards 2018? You’re welcome to join us at the Awards ceremony and the Sustainable Packaging Summit at Scanpack in Gothenburg on 23 October 2018. Contact Packaging Europe by email or Twitter for details.