Counterfeiting has moved on from small-scale operations to big business. Elisabeth Skoda shines a light on solutions as aimed at luxury packaging, pharmaceuticals and fast-moving consumer goods ranging from holograms to printed on-pack and on-blister codes and RFID-powered flexible electronics.

The global market for anti-counterfeiting, brand protection and security packaging will reach $3.09 billion in 2019, according to a report from Smithers Pira. Innovation and increased demand – especially in supply chain security applications – will see market growth at an annual rate of 4.4 per cent through to 2024; driving total value to $4.05 billion in that year. The report identifies the globalisation of distribution, combined with rising concerns over counterfeit goods as factors that are boosting greater demand for anti-counterfeiting solutions. Furthermore, the digitalisation of logistics and e-commerce trade is also posing a challenge for manufacturers of physical security components of how to form a link to the online world.

The benefits of holograms

Counterfeiters today often run major operations with entire factories featuring advanced technology facilities. Integrating different technologies into single security elements, such as holograms connecting with track-and-trace systems, integrating holograms directly onto the product without any additional materials/layers and sophisticated holograms with special visual effects can offer extra security, as Petr Franc, the divisional director for security at Prague-based company IQ Structures points out.

He explains how holograms can help the industry to keep up with ever more sophisticated counterfeiters.

“Offering the possibility to emboss holograms directly onto a pack is ideal for luxury packaging. They can be embossed on all types of plastics and as well as metals. We produce master holograms with a diffractive structure tailored for particular packaging materials. We also offer our clients the tools to enable them to replicate holograms using their own production technologies,” Mr Franc explains.

Managed nanostructures and microstructures on holograms offer features such as water resistance, heat stability and an irreversible change of colour if warehousing conditions are broken.

“Our computer-generated holograms feature a sophisticated diffraction strategy that is virtually inimitable,” Mr Franc adds. “The holograms include unique visual effects and are self-destructive. Any attempt to manipulate them results in a disintegration into tiny pieces. Product data can be written on them and they can be integrated with track and trace systems.”

He foresees an extended role for holograms in the near future:

“I expect the ability to customise security elements, including writing critical product data on holograms, facilitating simpler checks and thus enabling customers to check authenticity for themselves.”

Making online pharma safer

Counterfeit products are receiving a boost due to the growth in online pharmacies.

“A lower price can be enough to fool many unassuming consumers to buy from unproved sources that look like legitimate businesses. A Dutch study cited by the International Journal of Clinical Practice found that of 370 seized Viagra samples, only 10 were genuine,” says Kajsa Dahlin, group innovation manager at A&R Carton.

In order to make medication safer, A&R Carton has developed technologies that work on the box and on the blister respectively.

“Noise print, developed in partnership with anti-counterfeit specialist Cypheme, offers in-line direct-on-pack standard printing such as in gravure or offset. It is printed in analogue and data is added to connect that specific product in the cloud, turning it into a virtual code,” Ms Dahlin adds.

The code is photographed in-line and stored on a secure server. It can be photographed and confirmed anywhere in the supply chain if the camera system is in place. Once the pack is on the market, consumers themselves can snap a picture of the pack in-store and get direct authentication of the products.

“Due to the nature of the noise print material, the small fingerprint created on each box is a completely randomised microstructure. Replicating a noise print is virtually impossible due to the resolution and detail level of the marks and its anti-copy layer printed with a special ink outside the standard colour gamut,” Ms Dahlin adds.

Protecting individual blisters

In certain geographical markets, a product is sometimes sold in individual blisters, which makes security noise print lose its value. For those cases, a foil marker on the individual blister packs, like the one developed by AR Packaging in cooperation with barcode specialist Digimarc can work best, as Ms Dahlin points out:

“The foil marker is a solution especially suitable for cases when the product is taken out of their secondary packs to be sold individually, as sometimes happens in some African and Asian countries. The foil markers can be placed directly on each blister pack during standard printing, and offer a way for consumers to authenticate securely with their smartphones, as the foil markers are incredibly hard to copy. If the marker is scanned or photographed, the metallic background interferes with the reading and the reproduced marker will be unreadable.”

Addressing the grey market challenge with flexible electronics

While counterfeiting has challenged industry forever, in recent years, another problematic subject has emerged – the grey market, featuring products that are not counterfeit but are sold outside approved supply agreements. In general, the goods are bought in a low-price country, and then sold elsewhere, where they command a much higher price. There are also goods that are meant for use in service outlets but then appear on supermarket shelves.

Whilst it is not illegal to buy from grey market sources, consumers often find the experience less than satisfactory when products come without local language instruction manuals, the usual accessories, or the brand owners refuse to repair or replace an item when something goes wrong. Brands are expected to close down grey market channels, but the challenge is to find out where the supply chain has been disrupted.

Flexible electronic tags are a potential weapon against grey market, as well as counterfeiting – using blockchain and cloud-based services to track goods from manufacture to the end consumer. However, the overheads of using standard solutions for lower price FMCG would be too high when adding the cost of implementing blockchain on top, as Rachel Baker, marketing manager at PragmatIC points out.

“Counterfeiting nowadays is not limited to high value and luxury items, it covers the whole price range. Printing quality has improved so much, making it a lot easier to produce convincingly packed products at a low cost. For consumer goods, where the price of the packaged goods is £10/10€ or less, it is not economically viable to support the high price of silicon-based electronics, creating a need for lower cost flexible electronics.”

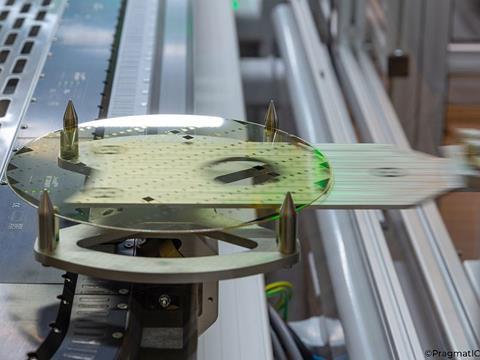

PragmatIC’s ConnectIC family of flexible RFID circuits, launched in February this year, bring cost-effective digital traceability and interactivity to everyday objects, as Gillian Ewers, PragmatIC’s marketing VP, claims.

“ConnectICs are designed on PragmatIC’s technology platform which delivers flexible integrated circuits that are thinner than a human hair. They are designed to be used with single layer antennas, which dramatically reduces total inlay costs. They are flexible and robust, which enables them to withstand the rigours of consumer goods packaging and use. Large bond pad sizes allow for more relaxed placement and bonding tolerances. ConnectICs are compatible with both conventional pick-and-place machines and higher throughput parallel assembly. Fast read times ensures verification of the inlay can be performed at standard production line speeds and no customer encoding is required. In addition, they don’t require a battery, as they harvest energy from the antenna. The absence of a battery does further help to save space,” she says.

“Conventional solutions can leave a bump. An undetectable solution can be better as you don’t necessarily want the entire supply chain to know that there is a tracker in the product. If it is undetectable, it enables auditing the entire supply chain and finding out where a potential problem lies,” concludes. Ms Baker.