A San-Francisco start-up, Primitives Biodesign, claims to have developed the first compostable bioplastic product with inbuilt sensing functionality. Fin Slater spoke to Noa Machov, the company's Co-Founder and Director of Sustainability, to learn more about this innovative development.

Could you introduce Primitives to our readers and tell us about its mission?

Primitives is a biomaterials company based in San Francisco, CA. Founded in 2019, Primitives engineers thin films with remarkable properties, to be used in packaging and other applications. They sense and respond to the environment, enabling brands to monitor quality, improve safety, and reduce the environmental footprint of their products. Primitives films offer added sensing functionality to the growing bioplastics market, which has never been seen before. Our mission is to create a world where the materials around us are intelligently engineered and don’t overstay their welcome.

Please could you explain the history/R&D process behind your sensing bioplastic product?

Primitives films are based on a toolkit of biomaterials with sensing and display properties. Viirj Kan and team developed this core technology at MIT.

The team was inspired by the range of functional materials of natural organisms and wanted to use them to engineer smarter materials. Initial prototypes for the stimuli-responsive biopolymers were developed during their time at MIT, where they published the work in Association for Computing Machinery SIGCHI. It was granted a Best Paper Award at the CHI 2017 conference. As committed advocates for environmental stewardship, they found an application for their materials in the thin film packaging space, where plastics are an interface between humans and the environment.

What are the functions of this innovation and how does it work?

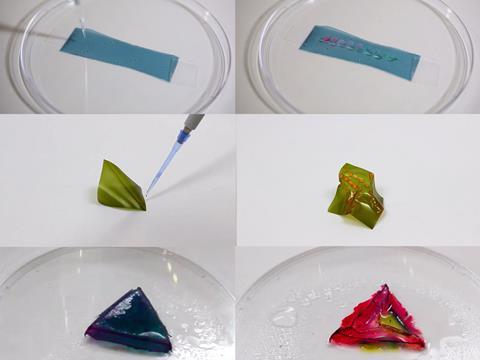

We’re inspired by the diversity and embedded intelligence of biological systems – from chameleon skin that changes colour, plants that emit odour, pinecones that change shape to emit seeds at optimal humidity, and hydrophobic coatings on banana peels. Because our films are made using biologically derived molecules, Primitives films incorporate sensing mechanisms similar to those seen in nature. This enables them to sense and respond to their surroundings. These functional films can be integrated into applications across industries. For example, supplement packaging that changes colour when it’s been tampered with or punctured. Insulin labels that respond to extreme temperature, telling you it’s no longer safe to use. Milk that tells you it’s gone bad, without having to smell or taste it.

Please unpack your claims that your technology is compostable – what ingredients is it comprised of, does it have independent certifications, and how can it be composted?

Primitives film layers degrade faster than other bioplastic alternatives, such as PLA, and are compostable within 10, 20, or 30 days. They exhibit tunable degradation ranging from 20% to 70% mass loss over 3 weeks. These films are made from renewable materials like algae and other bio-based feedstocks. We have run our own preliminary tests for home compostability and are in the process of attaining independent certifications.

Commercially, how far away are your products from market and how will you be looking to make them truly scalable?

Primitives is going to market with a 100% compostable, oxygen-proof film, for use in premium cannabis packaging. This high margin industry has a growing demand for new packaging innovations due to regulatory requirements. Next, Primitives will offer functionalities to improve product freshness and safety, and later provide sensing properties for environmental monitoring. As cost is a challenge for the bioplastics industry, Primitives has a plan to ensure they can scale to produce affordable films. When Primitives scales to pilot production through automation, they will decrease their costs by over 2000%. This will allow them to sell 1000 sq. foot rolls of our films at prices comparable to current premium films used in cannabis packaging. By production scale, Primitives will optimize their film thickness and increase their yield, allowing them to sell their rolls at prices that are competitive with other bioplastic films currently on the market.

What does the future hold for Primitives – are there any other product announcements on the horizon?

In the next year, customers can expect to see exciting new Primitives bioplastics products hitting the market. If you are a brand and would like to partner, Primitives is looking to partner with sustainability-minded brands in the health and wellness space to launch pilot products and co-develop novel, advanced bioplastic solutions.