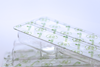

TekniPlex Healthcare and Alpek Polyester have developed the ‘world’s first’ pharmaceutical-grade PET blister film containing post-consumer recycled content, which will be showcased at Pharmapack 2024.

Reportedly, 30% of the film is made of post-consumer recycled monomers. To achieve this, post-consumer plastic waste is depolymerized in a chemical recycling process to break it down into its monomer building blocks; these are then repolymerized into PET, which is said to produce a recycled resin with the same properties as virgin plastics.

Conventional mechanical recycling methods can apparently facilitate the depolymerization process – which, in this case, takes place in Alpek’s polymer reactor and produces a master reel made according to the melt-to-sheet process.

The new blister film is said to meet all requirements for PET in pharmaceutical applications as per the European Pharmacopoeia Section 3.1.15, and United States Pharmacopoeia Section 661.1. In turn, its integration into pharmaceutical operations is expected to help pharma companies keep on top of developing sustainability legislation, including recyclability deadlines and PCR content baselines laid out in the EU’s Packaging and Packaging Waste Regulation.

TekniPlex highlights that the film can be combined with its Teknilid Push polyester lidding to achieve full recyclability in the polyester recycling stream wherever the relevant infrastructure exists. It is hoped that the solution will unlock more sustainable pharmaceutical packaging solutions without impacting material quality, product protection, or patient health.

Melissa Green, head of Global Marketing for TekniPlex Healthcare, commented: “This is the first time pharmaceutical companies have the option to incorporate a blister pack that is fully recyclable and, at the same time, contains a significant portion of recycled material – all while still meeting stringent pharmaceutical quality standards for product protection and consumer safety.

“We anticipate high demand for this new, more sustainable film, as it meets ever-growing calls for elevated eco-friendliness in packaging across all sectors, including pharma.”

Other packaging solutions to be presented by TekniPlex Healthcare at Pharmapack include the Pentafill A25 Filling & Sealing Machine. Designed for plastic containers, the machine is thought to optimize the features of its previous models with improved sterility, a smaller footprint, and more.

It can produce up to 25 five-vial strips per minute, totalling 123 vials. TekniPlex says the solution is compatible with various viscosities to ensure its compatibility with the pharmaceutical, diagnostics, nutraceutical, and animal health markets.

Additionally, its pharma rubber compounding and manufacturing solutions for healthcare applications will also be on display. These include gaskets and closures.

All have been manufactured to precise dimensional tolerances to fit and function appropriately in packaging and medical device applications, TekniPlex asserts. They are set to lower the risk of extractables, leachables, and other migration-associated impurities.

The company also underlines its ability to develop and test unique rubber solutions tailored to individual customer applications at its laboratories.

In a previous development, TekniPlex Healthcare revealed what was claimed to be the world’s first fully transparent and recyclable mid-barrier blister package. Consisting of a polyolefin blister film and a barrier polypropylene lidding film, it is said to be compatible with polypropylene recycling streams.

Since then, Schreiner MediPharm has partnered with Keystone Folding Box Co. to develop a child-resistant, senior-friendly blister packaging solution featuring integrated electronics to capture dosing history data.

Coveris has also revealed its flexible medical packaging solutions, Formpeel P and Formpeel T, at the COMPAMED show in Düsseldorf. These have been designed to maintain the functionality and safety of conventional materials through recyclable alternatives that, according to the company, minimize packaging and product waste.

Also at Pharmapack 2024, Berry Global Healthcare will show a range of its pharmaceutical packaging solutions. These include a new dry powder inhaler for combination drugs; an ophthalmic nozzle designed for safe and reliable administration; and a child-resistant closure featuring digital technology for improved medication adherence.

If you liked this article, you might also enjoy:

The Lidl approach to packaging sustainability

How did Brazil achieve its 100% aluminium can recycling rate – and can it be replicated in the EU?

Experts have their say on the EU’s Packaging and Packaging Waste Directive revisions

A deep dive into the most important packaging sustainability trends and solutions

No comments yet