Stora Enso has introduced Ensovelvet, its new uncoated solid bleached sulfate (SBS) board developed for luxury applications such as cosmetics, perfumes, and other premium consumer goods.

Designed to meet demand for natural and renewable solutions in luxury packaging, Ensovelvet is said to offer a ‘unique combination’ of a natural uncoated surface, excellent stiffness and reliable folding performance. The board aims to provides an enhanced sensory experience while ensuring excellent printability.

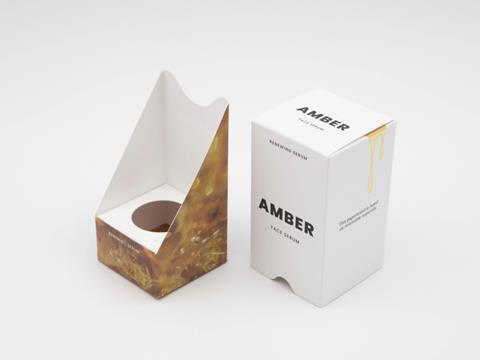

Stora Enso says its new board is well-suited for cosmetics packaging, perfumes, and other high-end applications where touch and appearance are equally important. It adds that Ensovelvet complements its flagship Ensocoat board, which together form a complete SBS carton range for brand owners and converters seeking versatility across coated and uncoated applications.

The company states that both boards are recyclable, and the absence of coating in Ensovelvet also means fewer materials are needed in production, resulting in a reduced carbon footprint while maintaining the performance expected from premium packaging materials. Ensovelvet is available from 240 g/m2 to 320 g/m2 and will be presented to visitors at LuxePack Monaco, 29th September – 1st October 2025.

In April, Stora Enso unveiled its Performa Nova folding boxboard (FBB), designed to meet growing demand for renewable and recyclable packaging in segments such as dry, frozen and chilled food, chocolate and confectionery. The new packaging is produced using FiberLight Tec, the company’s proprietary technology for creating ‘strong yet lightweight’ board.

As part of our Sustainability Perspectives podcast series, this month editor-at-large Elisabeth Skoda spoke with YUTOECO’s Jerome Zhang about some of the recent innovations and challenges in the area of dry moulding fibre technology for packaging. Also this month, building on the introduction of its Uncoated Fibre series, Metsä Spring has announced it is now preparing the Muoto Laminated Fibre series, a new solution that combines moulded fibre products with barrier films, for industrial testing. Developed in collaboration with Amcor, the solution is now moving into an industrial testing phase with selected customers.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet