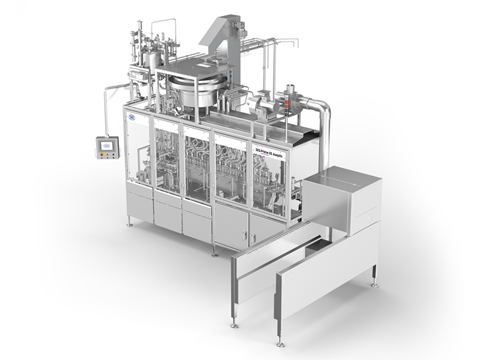

SIG has unveiled a new filling system for pre-made, spouted aseptic pouches, designed for in-line pouch sterilization, a simplified supply chain, and lower production costs.

The SIG Prime 55 In-Line Aseptic aims to negate the need for third-party pre-sterilization of spouted pouches. It has now reached commercialization and was featured in conversations at the 2024 Anuga FoodTec exhibition in Cologne, Germany.

“SIG has a considerable history in development of leading technology for aseptic packaging,” said chief markets officer Christoph Wegener. “Customers around the world look to SIG for the latest innovations to propel their brands into the future and the SIG Prime 55 In-Line Aseptic pre-made spouted pouch system is the next in a long line of those innovations.

“This new filling system offers technological progress by transferring SIG’s expertise in aseptic filling technology with in-line sterilization, which has been successfully in use for decades in the field of carton packs, to spouted pouches. The breakthrough here is a new and unique way of sterilizing spouted pouches in-line, ensuring sterilant flow and coverage of the packaging while it’s in the filling tunnel.

“By eliminating the need for pre-sterilization of the pouches, we’re able to give producers full control and flexibility of their production. This is an exciting time for SIG and an important step forward in our journey to enable brands to produce more nutritious foods for better.

“We are extremely proud that we will soon be trialing the system with recycle-ready SIG pouches. They will be a world first in our industry.”

Massimo Annaratone, global business line director of Spouted Pouch, continued: “Aseptically packaged food and beverages retain their high quality and can be stored for a long period without refrigeration or preservatives. Resulting products like fruit puree, sauces, and baby food taste great and maintain nutritional value.

“With the SIG Prime 55 In-Line Aseptic, we have further advanced the potential reach of better nutrition through a system that combines quality, SIG-produced spouted pouches with proven in-line sterilization technology delivering >log 5 reduction in production. The conversion from retorted and hot-filled products in cans, plastic bottles, and glass to convenient aseptic spouted pouches has never been more compelling.”

Earlier this year, Syntegon’s Ampack revealed a flexible FBL filling machine with neck-handling capabilities for preformed HDPE, PP, and PET bottles. It is designed to gently and aseptically fill containers with baby food, milk- and plant-based drinks, dairy products, and soups.

Meanwhile, ACG’s AF330 capsule filling machine for pharmaceutical and nutraceutical applications aims for high output, low maintenance costs and footprint, and minimal unplanned downtime. It was displayed at CPHI and PMEC India 2023.

If you liked this story, you might also enjoy:

The Brief: How viable is biorecycling for plastics?

Report: How the top brands are progressing on packaging sustainability

The Brief: Using ocean-bound plastic in packaging – how, why and should we?

No comments yet