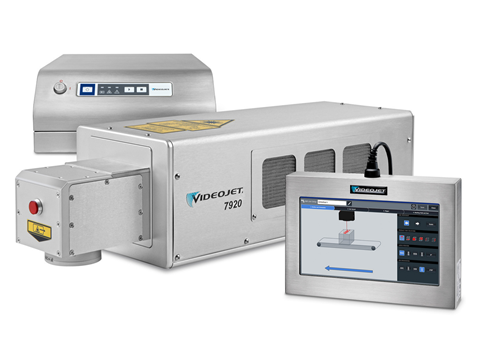

Videojet Technologies has announced its new 7920 UV laser marking system aiming to boost ease-of-use, flexibility and reliability in coding operations for the consumer packaged goods, parts marking and pharmaceutical industries.

The company says its new system incorporates Videojet SmartFocus technology to reduce the need for manual adjustments. To simplify product changeovers and help with consistent code clarity, it has multi-level surface marking, an auto-adjustable focal distance, uniform flat field correction and a pilot beam focus finder.

According to Videojet, the system also has integration features, high-quality code production and a five-year source warranty, hoping to give companies confidence in their production lines. The Videojet Remote Service (VRS) is said to minimize downtime for 7920 users through maintenance alerts and software updates, seeking to reduce unexpected downtime and boost productivity.

Reportedly, the laser source will be proactively monitored to help mitigate the risk of unexpected downtime. The 7920’s compact design and beam turning units allow for a 360-degree rotation, and it comes with IP54 environmental protection and an optional IP65 rating for reliable operation in a range of conditions.

Videojet states the 7920 UV laser delivers ‘superior codes’ on applications like white HDPE containers and mono-materials. It adds that the new laser can mark at speeds up to 2,000 characters per second.

The 7920’s digital features include cellular and Wi-Fi connectivity options for secure remote interface control and analytical capabilities, apparently engineered to assist manufacturers in minimizing IT time and investment and boost overall equipment efficiency.

The company revealed its 9560 automated labelling system for outer cases, boxes and shrink wrap in July, designed to improve operating performance with a direct drive that controls label speed and position without clutches, rollers or adjustments. It was also said to feature increased processing speeds and expanded connectivity options.

More recently, Procter & Gamble and LasX Industries developed a direct-to-package laser marking technology to replace conventional label application methods with label-free packaging. It claims to enable access to the entire surface of a pack, reaching areas that cannot be accessed with pressure-sensitive labels, shrink film, or direct ink printing.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet