Researchers from RMIT University in Melbourne, Australia, Tokyo Metropolitan University, and Mitsubishi Chemical’s The KAITEKI Institute have created an antibacterial nanotexture for rigid plastic packaging based on the structure of insect wings that can kill bacteria by pulling, stretching, or slicing them apart.

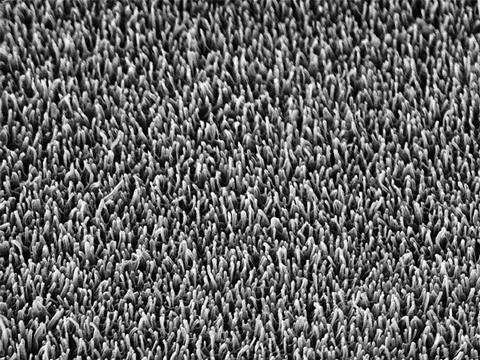

The wings of dragonflies and cicadas are covered in nanopillars, which are blunted spikes of similar size to bacterial cells. According to the research team, when bacteria settle on the wing, the pattern of the nanopillars pulls the cells apart, in turn rupturing their membranes and killing them. Previous research has examined the nanomaterials’ potential to fight superbugs, such as those resistant to antibiotics.

Distinguished Professor Elena Ivanova of RMIT University explains: “It’s like stretching a latex glove. As it slowly stretches, the weakest point in the latex will become thinner and eventually tear.”

Ivanova’s team at RMIT University, the Mechano-bactericidal Materials Research Group, developed a nanotexture that replicated the insects’ nanopillars, thus creating nanopatterns of their own. The antibacterial properties of these nanopatterns were then monitored at RMIT’s Microscopy and Microanalysis Facility.

The most effective antibacterial patterns were then shared with the team in Japan, who developed a way to reproduce the patterns on plastic polymers. The Australian team later tested the plastic nanopatterns, in order to identify the one that best replicated insect wings while being easiest to fabricate and scale up.

The research team claims that the nanotexture developed in the laboratory kills up to 70% of bacteria, reportedly retaining its effectiveness when transferred to plastic. The team suggests that the nanotexture could be used in packaging to reduce waste both during exports, as entire shipments can be rejected if bacterial growth is detected, and while on the shelf.

Ivanova adds: “Eliminating bacterial contamination is a huge step in extending the shelf life of food.

“We knew the wings of cicadas and dragonflies were highly-efficient bacteria killers and could help inspire a solution, but replicating nature is always a challenge.

“We have now created a nanotexturing that mimics the bacteria-destroying effect of insect wings and retains its antibacterial power when printed on plastic.

“This is a big step towards a natural, non-chemical, antibacterial packaging solution for the food and manufacturing industry.”

Ivanova and her colleagues apparently discovered the bacteria-killing nature of insect wings a decade ago, but add that until recently, it was difficult to find suitable technology to reproduce this nanotexture on an appropriate scale for manufacturing. The research group says that the technology now exists to scale up and apply the antibacterial nanotexture to packaging, along with other potential applications, such as personal protective equipment.

In addition, working with plastic provided another challenge due to its flexibility. The research team explains that this made it more difficult to use than other materials like silicon and metals.

According to Ivanova: “The nanotexturing created in this study holds its own when used in rigid plastic. Our next challenge is adapting it for use on softer plastic.”

The team concludes that it is keen to collaborate with potential partners in the next stage of the research, which will involve upscaling the technology and determining the best ways to mass manufacture the antibacterial packaging.

The research was supported by the Foundation for Australia-Japan Studies under the Rio Tinto Australia-Japan Collaboration Project. Ivanova’s co-authors include Denver Linklater, Soichiro Saita, Takaaki Murata, Chaitali Dekiwadia, Russell Crawford, Hideki Masuda, and Haruhiko Kusaka.

Globally, there is a growing amount of research and development in the field of antimicrobial food packaging. For example, the European FLEXPOL project has developed an antibacterial and antifungal plastic film using nanoencapsulated essential oils.

No comments yet