PepsiCo has announced a multi-year collaboration with Siemens and NVIDIA, aiming to transform its plant and supply chain operations through advanced digital twin technology and AI. Digital twins will be applied to reshape how plant and warehousing facilities are digitally simulated and tested, with early pilots underway in the U.S.

Said to be a ‘first-of-its-kind’ initiative for a global CPG company, PepsiCo is utilizing AI and ‘new digital approaches’ to process simulation and facility design, to retool and optimize its existing physical footprint. The company says it is shifting to a digital-first planning strategy, leveraging physics-based digital twins and AI agents as co-designers to simulate, validate, and optimize facility layouts before any physical build.

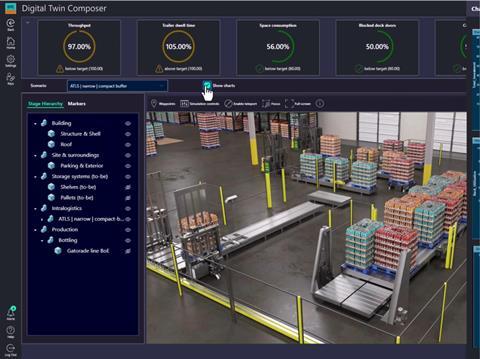

PepsiCo is using Siemens’ Digital Twin Composer, built on NVIDIA Omniverse libraries, to simulate upgrades to its facilities in the U.S. with plans to scale globally. Siemens’ new software solution builds Industrial Metaverse environments at scale, designed to enable organizations to apply industrial AI, simulation and real-time physical data to make decisions virtually, at speed and at scale.

This new product enables industrial companies to combine 2D and 3D digital twin data from Siemens’ digital twin and physical real-time information from a managed, real-time photorealistic virtual scene accelerated by NVIDIA Omniverse libraries. Apparently, companies can use the Digital Twin Composer to rapidly build and maintain this global environment, containing all aspects of their product or production data (both virtual and physical) in a secure 3D experience throughout the lifecycle of the product, process or facility.

Leveraging Siemens’ and NVIDIA’s technologies, PepsiCo states it can now recreate every machine, conveyor, pallet route and operator path with physics-level accuracy, enabling AI agents to simulate, test, and refine system changes - identifying up to 90% of potential issues before any physical modifications occur. Reportedly, this approach has delivered a 20% increase in throughput on initial deployment and is driving faster design cycles, nearly 100% design validation and 10%-15% reductions in capital expenditure (Capex) by uncovering hidden capacity and validating investments in a virtual environment.

In related news, Nestlé unveiled its AI-powered, in-house service last summer, which utilizes digital twins to digitally adjust or localize packaging for seasonal campaigns, channel-specific formats like e-commerce and digital media, and other redesign requirements. Created in partnership with Accenture Song, the content service is designed to generate 3D replicas of physical products, with Nestlé claiming to have reached a baseline of 4,000 3D digital master products, predominantly for global brands like Purina, Nescafé Dolce Gusto, and Nespresso.

The following month saw Unilever, Amcor, and Asahi reveal that they were trialling Deepnest, Greyparrot’s ‘world-first’ AI waste intelligence platform that provides brands with product-level recyclable waste data and addresses knowledge gaps. Designed to track packaging performance by brand, material, product type, and region, AI-camera systems in material recovery facilities follow packaging through the waste system and record which units are sorted, recycled, or lost.

If you liked this story, you might also enjoy:

The ‘complex reality’ of reusable packaging in Europe

Single-use packaging versus reusable packaging: Which is more sustainable?

The ultimate guide to global packaging sustainability regulation

No comments yet