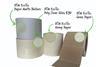

In an expansion of its EasyLine range, Robatech is offering a lightweight thermoplastic hot-melt adhesive application system for simple applications like trays, folding boxes, paper cups, and sleeves for ice cream cones.

Thought to be one of the lightest adhesive melters available at 16kg, the system consists of Robatech’s new Easy adhesive melter, Rio heated hose, and Twist jetting head. It is designed to serve as an easy-to-use, compact solution for easy and secure gluing while combining minimalism with practicality.

Its head holder is adjustable in 22.5° increments and the position of its application nozzles is variable. As such, the jetting head is thought to be flexible and easy to install in machinery.

In a bid to streamline adhesive replacement, the filter is now located at the fully insulated connector in the heated hose. This is said to cut down on time-consuming removal and insulation and keep the application head clean.

Robatech asserts that EasyLine offers ‘all the necessary functions’ for simple adhesive applications with its manual pump pressure control, temperature lowering and heating zone management for the adhesive melter, heated hoses and application heads. Apparently, it is easily connected with plug-and-play connectors.

“The maximum melting capacity of 2.5 kg/h and two heated hose connections offer perfect conditions for simple adhesive applications,” says André Laubacher, responsible product manager at Robatech. “Customers enjoy the functionalities they really need and benefit from fast commissioning and maintenance, as well as an attractive price-performance ratio.”

The announcement comes after Robatech’s previous release of PerfectFold, its liquid creaser for adhesive application systems. It is geared towards quick, precise folding for corrugated cardboard and drive the box assembly process.

In other news, Henkel Adhesive Technologies has revealed DAREX WBC 711, a new sealant for food cans. It is said to lower Greenhouse Gas Protocol emissions by over 30% compared to the existing DAREX OP 2928 compound, excluding the use phase and end-of-life emissions.

H.B. Fuller also presented a range of pressure-sensitive adhesives at Labelexpo Europe 2023. They were designed in pursuit of high-quality aesthetics, clean label removal, and a reduction in carbon emissions.

If you liked this article, you might also enjoy:

The L’Oréal approach to packaging sustainability

The way we talk about plastic needs to change – here’s how to get it right

What steps is Apple taking to make its packaging more sustainable?

No comments yet