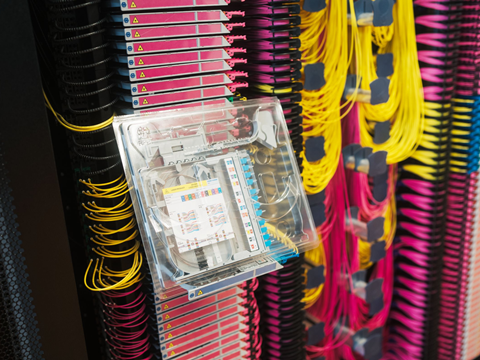

Huber+Suhner has reportedly packaged its fibre modules in blister packs made from 100% recycled PET – a move hoped to minimize waste and halve CO2 emissions compared to traditional packaging solutions.

Applied to its LISA and IANOS fibre modules, the new packaging is designed with a universal fit to apply to every version of the products, from left-or-right hand cassettes to standard and ribbon versions. This is hoped to negate the need for multiple packaging types while streamlining supply chain logistics.

Similarly, the pack is stackable – a feature intended to improve space efficiency in transport and storage, thus lowering operational costs and transit-related emissions.

A dust-proof seal has been implemented into the design to prevent contamination, which in turn avoids repackaging and cuts down on unnecessary waste. The pack is also designed to offer high performance and maintain durability.

Altogether, Huber+Suhner aims to lower CO2 emissions by 50% compared to conventional fibre module packaging, while also optimizing resource efficiency and achieving ‘superior’ product protection.

“This latest initiative represents another important milestone in our ongoing journey to drive sustainability across our operations,” said Lana Ollier, head of Global Sustainability at Huber+Suhner. “By integrating recycled materials and optimising logistics, we are providing our customers with a high-performance operations solution that aligns with their as well as our environmental goals.”

Last year, Bayer and Liveo Research unveiled a ‘first-of-its-kind’ PET blister pack for the over-the-counter drug brand Aleve. Apparently, its elimination of PVC unlocked a 38% reduction in the pack’s carbon footprint.

We spoke to Chris Padain, vice president and head of Design and Packaging at Bayer’s Consumer Health Division, to hear more about its development; the challenge of meeting regulatory requirements in the healthcare industry, the process of tailoring the product to consumer preferences, the LCA conducted to establish its carbon footprint, and more.

In other news, SÜDPACK Medica has unveiled a mono-polypropylene blister solution for nutraceutical product packaging. It aspires to maintain contact safety and product performance while aligning with the Packaging and Packaging Waste Regulation’s recyclability requirements.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet