Label and packaging provider Masterpress has announced its participation in the EU-funded BeFORE Barrier for Recycling initiative, with its single-layer, non-laminated stand-up pouch for liquid soap being tested for high-barrier recyclability.

The BeFORE consortium runs from 1 March 2025 to 28 February 2027 and includes industrial manufacturers, research institutions and packaging value-chain organizations from Belgium, Germany and Poland. Masterpress participates in the project through Natureef, a Polish association bringing together companies from the packaging, food production and recycling sectors under joint research projects.

BeFORE aims to ensure that mono-material packaging designs are also recyclable and deliver essential barrier performance. The project studies the real-world performance of materials and thin functional barrier layers which can be more vulnerable to damage during filling, sealing, folding, thermoforming and handling.

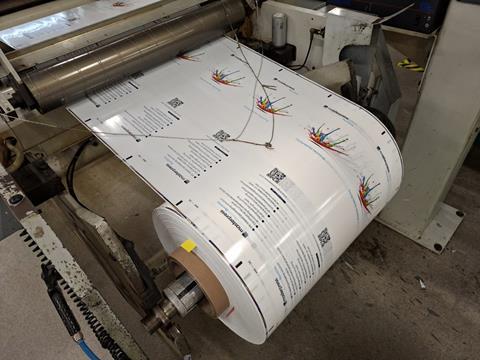

As part of BeFORE’s work on high-barrier, co-extruded polyethylene (PE) stand-up pouches, Masterpress has contributed its single-layer, non-laminated stand-up pouch for liquid soap. The company says the pouch is made from a single mono-material PE/EVOH structure, engineered to sort correctly in recycling facilities and work within existing PE recycling systems.

The pouch is being tested in several areas including barrier performance; strength and shelf-life behaviour, especially for liquid soap formulations; safety and migration assessments, in line with regulatory requirements; performance on automated filling and packaging lines and recyclability, evaluated according to international recyclability guidelines.

The project’s findings will apparently feed into broader industry guidance including the development of a comprehensive White Paper, best practices for design-for-recycling, and case-study evaluations across multiple material categories (paper, plastic, and hybrid structures). BeFORE’s scientific evaluations covering functional performance, sortability, recyclability and safety, seek to support industry readiness for upcoming mandatory requirements including the Packaging and Packaging Waste Regulation (PPWR).

In related news, Sappi Europe launched its Guard Pro OHS and Guard Pro OMH mono-material papers in September, said to be recyclable and deliver high-barrier protection without compromising production efficiency. The new solutions are designed to help brand owners meet tightening EU packaging regulations such as the PPWR and offer a paper-based alternative to plastic and multilayer foils for fast-paced manufacturing lines.

The following month saw Siegwerk, Borouge, and TPN Food Packaging (TPN) collaborate on a fully recyclable, mono-material barrier stand-up pouch said to provide robust protection and superior functionality. The solution aims to meet the needs of converters, brand owners, and consumers seeking sustainable, high-performance packaging for oxygen-sensitive, dry products such as nuts and pet food.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet