A new bulk adhesive range from Power Adhesives seeks to unlock low-waste, large-scale and efficient sealing for packaging, among other industrial applications.

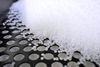

Included in the range are pillow and prills formats for high-output adhesive requirements – fast-setting adhesives for carton sealing and product assembly; sprayable adhesives for mattress assembly and foam converters; and high-heat-resistant adhesives for demanding industrial applications.

Each is designed to reduce waste, improve efficiency, and meet increasing demand for large-scale adhesive solutions. Offering adhesives in bulk is set to help businesses streamline their processes by cutting down on handling time and achieving consistent bonding quality at scale.

It is also set to give customers more flexibility to match their application with the ideal adhesive, especially in light of a growing desire for cost-effective and sustainability-minded solutions.

“Our bulk adhesive range is a natural evolution of our product offering, driven by industry demand for scalable, high-performance bonding solutions,” explained Brendan Colgan, CEO of Power Adhesives. “We have built a reputation for delivering adhesives that enhance efficiency and reliability, and this expansion ensures that customers have even greater choice when selecting the right adhesive for their needs.

“By introducing bulk formats alongside our Tecbond range, we are giving manufacturers the ability to maximize productivity while reducing waste. Whether it’s packaging, product assembly or large-area bonding, our bulk adhesives provide a solution that combines strength, efficiency, and sustainability.”

The news comes after the release of Power Adhesives’ Tecbond 214B, which claims to be the ‘world’s first’ fully certified biodegradable hot melt adhesive and is also available in bulk. Manufactured with 44% biobased materials, the adhesive is designed to completely break down in the presence of oxygen without leaving microplastics behind.

Other sustainability-minded adhesives unveiled in recent months include Henkel Adhesive Technologies’ Technomelt Supra 079 Eco Cool, a hot melt adhesive containing 49% directly biobased raw materials and 30% ISCC-certified mass-balanced material. The solution is set to save an annual 7,500kg of CO2 in folding carton, tray, and wrap-around packaging applications.

Meanwhile, the REDYSIGN project reports ‘interesting results’ in its efforts to use fibre as an adhesive in film-tray applications – forming part of its efforts to develop recyclable, wood-derived packaging alternatives for fresh meat products.

If you liked this story, you might also enjoy:

Reuse vs. single use – which is better for the environment?

Sustainable Innovation Report 2025: Current trends and future priorities

What can the world learn from South Korea’s world-leading performance in plastics circularity?

No comments yet