Baumer HHS has introduced Xmelt fusion, its latest range of melters designed for hot melt applications, seeking to enable customers to optimize their processes in the packaging industry.

Martin Kotecki, packaging business development manager at Baumer HHS, says that company’s goal was to achieve a maximum melt rate while minimizing volume and energy consumption and maximizing reliability in production. Kotecki adds that the Xmelt fusion generation can reach a melt rate of up to 14 kg hot melt adhesive per hour with an energy input of 1.6 kW.

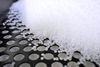

According to Baumer HHS, the range’s compact Basic unit can handle around 90% of all packaging applications and can be combined with an Xfeed system, which keeps it continuously supplied with hot melt adhesive granules and melts the conveyed adhesive on an as-needed basis. A Special Volume model with the same melt rate is also part of the Xmelt fusion series and can store non-conveyable adhesives near the tank, significantly minimizing the time and effort required for manual filling.

The Xmelt fusion melters can also be optionally equipped with a built-in 3.5” display or an external 7” display including a software solution for optimizing energy consumption and an indicator of how much adhesive is being consumed. Apparently, the new melters can be flexibly configured with ports for six or eight application heads, enhancing work safety for operators and minimizing energy dissipation.

In related news, last year Power Adhesives launched its ‘first-to-market’ biodegradable hot melt, designed for use by carton, corrugated packaging, point of sale (POS) converters and contract packers. The adhesive is certified to break down completely in the presence of oxygen, leaving behind only non-harmful products and no microplastics.

More recently, Henkel unveiled its new hot melt adhesive, Technomelt EM 335 RE, aiming to address the challenges of conventional hot melt adhesives and enable clean separation for labels on PET bottles. The new adhesive is said to have high performance and be ideal for paper and plastic labels.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet