Power Adhesives has announced the launch of its biodegradable hot melt adhesive, said to be a ‘world first’ and designed for use by carton, corrugated packaging, point of sale (POS) converters and contract packers.

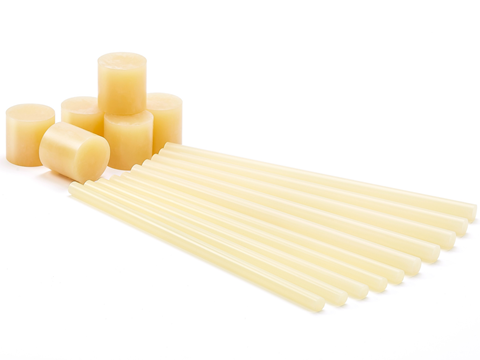

The adhesive is apparently certified to break down completely in the presence of oxygen, leaving behind only non-harmful products and no microplastics. Power Adhesives says its tecbond 2014B is manufactured with 44% bio-based materials and certified to ASTM D6400 and EN13432, the EU standard that sets out the requirements for compostable and biodegradable products.

Available globally, the company states that tecbond 214B offers the same performance characteristics as standard tecbond, with a high level of tack and fast setting speed providing an ‘almost instant’ bond once applied and compressed, aiming to enable companies to improve efficiency in packing procedures, workflow and output.

Power Adhesives adds that Tecbond 214B is indirect food contact approved and able to be utilized in all areas of the food packaging process, from wrap-around cartons and boxes to shipping packaging.

Brendan Colgan, chief executive officer at Power Adhesives, said: “This is an exciting time for the packaging industry. All players in the supply chain are working hard to drive sustainable products and processes into the market to support brands and consumers, and this is truly a groundbreaking moment for the packaging adhesives sector.”

In related news, Dow, Henkel Adhesive Technologies and Kraton Corporation announced in May that they had reduced the carbon footprint of two of Henkel’s hot melt adhesive formulas for end-of-line packaging. The TECHNOMELT SUPRA 100 LE and TECHNOMELT SUPRA 106M LE formulas, designed with biobased alternatives, are said to reduce adhesives’ cradle-to-gate carbon footprint by 25%.

More recently, Sasol Chemicals introduced SASOLWAX LC100, an industrial wax grade with a reported 35% carbon footprint reduction, said to achieve cradle-to-gate Product Carbon Footprint (PCF) benefits. Designed for use in packaging adhesives, the grade aims to deliver thinner adhesive application and enable high-speed packaging lines due to fast set times.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Reuse vs. single use – which is better for the environment?

The ultimate guide to global plastic sustainability regulation

No comments yet