Over the weekend interpack hit its stride, with crowds continuing to flood into Messe Düsseldorf.

Occurring every three years, interpack tends to serve as a snapshot, a gauge of how the industry has moved forward. In 2017 the most striking shift is undoubtedly the huge advances made in taking smart production from concept to reality. From Rockwell Automation's Best Future Machine awards to the special exhibition hosted by VDMA, there are hundreds of examples of Industry 4.0 applications that are delivering transformative improvements right now, even while much of the talk is about where we will be in 2020.

Bosch Packaging Technology gave practical demonstrations of how Industry 4.0 solutions can help achieve higher process safety and product quality in industries such as pharma and food. Detailed information about each machine, line or process status is provided by the Bosch's Condition Monitoring platform, which records data in real-time, enabling maintenance staff to react before cost-intensive process deviations or downtime occur. An example shown at interpack was the monitoring of filters, which ensure the consistent sterility of production processes. Special sensors within the machine control the sterilisation status of these filters. In case predefined parameters are infringed, operators receive a notification. This enables them to initiate maintenance activities quickly, and to prevent product loss due to non-sterile processes.

Meanwhile, Gebo Cermex displayed a number of world premieres relating to their 'Agility 4.0' concept - tailoring the possibilities of Industry 4.0 to facilitate efficient and agile supply chains in an age of urbanisation, customisation and e-commerce. The business is rolling out a host of solutions to realise the connected factory, with the iTRACK-powered Care Select feeding system (winner of Rockwell's 'Best Modular Machine' award), fenceless, laser guided robotics and the container handling technology AQFlex. Gebo Cermex also demonstrated its virtual factory simulation tools, which are bringing efficiencies in line design and training.

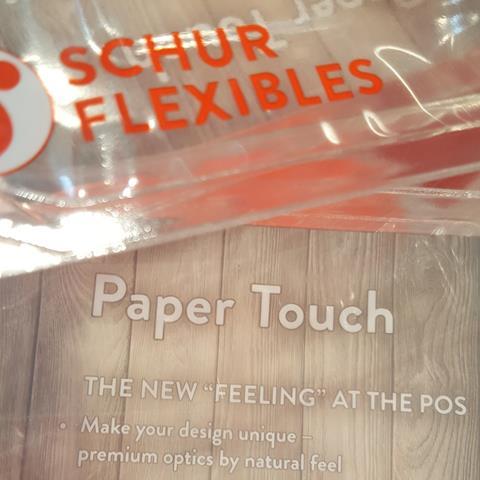

In the flexibles segment there were impressive examples of paper-like films, including Schur's Paper Touch and ultra-thin solutions from Sun Chemical that suggested the feel of tissue paper - with deceptive strength.

Sun Chemical showed off its famed scope of innovation, including a solution developed in conjunction with the University of Tokyo that helps brands test artwork from the perspective of the 10% of humans who suffer from the various forms of colour blindness. This simulation tool can help optimise design in order for logos and on-package communication to be clearly read by all consumers.

Both on the tna stand and at its giant satellite exhibit at Düsseldorf airport, the Australia-headquartered packaging-processing machinery specialist was celebrating both its 35th anniversary and the launch of its ropac 5, an ultra-high-speed case packer for flexible bags that can achieve speeds of up to 300 bags per minute. This advance is made possible by a revolutionary in-house innovation: revolving shelves replace the customary vacuum pick and drop. Meanwhile, the machine's narrow footprint fits into the same space as a vertical form-fill-sealer.

Meanwhile, Packaging Europe caught up with the Netherlands Packaging Centre (NVC), which is heavily promoting its innovative digital classroom concept to deliver the badly needed proliferation of packaging training and continuous education. The unique e-classroom model offers real-time interaction with tutors and fellow learners while dramatically reducing the time and costs involved - making in-work continuous learning more feasible than ever before. On display was the iconic Gouden Noot trophy for packaging innovation - Packaging Europe magazine took the opportunity to snap a selfie.