Plastics and rubber trade fair K is being held in Düsseldorf, Germany from the 8th -15th October this year, and we’ll be reporting on all the key moments.

In this article, we’ll be providing you with all the essential information about the event, including interviews, news, commentary and the standout innovations throughout the weeks running up to the event as well as during the show.

Pushing what’s possible in mechanical recycling: A conversation with P&G’s Lee Ellen Drechsler

At K 2025, P&G unveiled an innovation in mechanical recycling developed in collaboration with Lindner - Flexloop. The new process uses a solvent-based extraction process to remove impurities, odours, adhesives and printing inks from used plastic packs. Packaging Europe’s Elisabeth Skoda sat down with Lee Ellen Drechsler, Senior Vice President for Research and Development at P&G to discuss the recent launch, developments in mechanical recycling especially in the area of flexibles and the company’s sustainability pledges.

Read the full article here.

Colour and additive solutions with Holland Colours

Raymond Jongman talked us through Holland Colours’ colour and additive solutions at K 2025. The lineup sought to improve the UV performance of PET products and preserve the quality of their recyclate.

Recyclable packaging, ISCC certification, and more at Kuraray’s booth

We’re at K with Didier Houssier, Market Development Director EVAL to learn about co-creation, recycling, and the other solutions and themes that Kuraray is exhibiting at the show. Take a look!

Visit Kuraray at Hall A7, Booth D06 to learn more.

Braskem presents bio-based plastic solutions

Braskem’s Ellis van Dam told us about the company’s I’m green Bio-Based portfolio, and in particular a drop-in bio-based polyethylene solution which can help customers to bring down their carbon footprint.

Find Braskem at K2025 in Hall 6, stand D27.

Dow showcases flexible sustainable consumer packaging innovation

Dow’s Martin Hill showed us some of the company’s packaging innovations designed for recyclability, from prototypes pushing boundaries to packs already on the market, in particular a novel pouch for home and personal care with 35% recycled content from household waste. Marc van den Biggelaar also told us more about a pet food pack with 10% recycled content that is also fully made of polyethylene for easy recyclability.

Find the company in its own cube at K – The World’s No.1 Trade Fair for Plastics and Rubber outside hall 4.

Sustainable masterbatch innovation with Sukano

The Packaging Europe team visited Sukano’s stand, where Alessandra Funcia discussed the company’s new developments on display at the show, including masterbatch technology for BOPLA pouches with a special additive to allow compostability, as well as a fully bio-based PEF bottle.

You can find the company at K in Hall 8a, stand H28.

Discussing Husky’s newly unveiled packaging platform

On our tour round the show floor of K 2025 we visited Husky Technologies, where Glen Chessell told us all about the company’s launch of the new packaging molding platform and the newly unveiled high performance HyperSync machine.

Find out more at stand A61 in Hall 13.

Nestal’s In-Mold Labeling machine for thin-wall pails takes centre stage

Nestal is upfronting its Elios 5500 PAC system. Optimized for packaging applications, particularly In-Mold Labeling (IML) pails, it claims to reach a clamping force of 5500 kN and combine high precision with energy efficiency and stable process consistency.

The hybrid injection unit utilizes two-valve technology and reaches an injection speed of up to 1100 mm/s in its ‘High Power’ mode. It also achieves a maximum injection pressure of 2400 bar.

To ensure constant part weight within tight tolerances, the Elios 5500 PAC uses a high-precision RFC injection control system with dynamic control resolution in the millisecond range. These features are set to facilitate the production of pails with thin walls without compromising on cycle speed.

Due to its hybrid drive concept and energy recuperation – the kinetic energy generated during braking is directed to the electric motor of the main drive, converted into hydraulic energy, and stored – the clamping unit is set to save up to 50% of electricity compared to a fully hydraulic machine.

Apparently, the machine can produce around 3,8000 parts every hour with a cycle time of 3.8 seconds. Meanwhile, its dry cycle time is placed at around 1.7 seconds.

The company highlights the benefits of IML for material efficiency, CO2 reduction, and recyclability. At K Show, it has worked with Sabic to produce a 1L IML pail from polypropylene, said to weigh just 23 grams – according to Nestal, every pail required 15 grams of additional material twenty years ago.

See the Elios 5500 PAC machine, and the rest of Nestal’s lineup, at Hall 15, Booth D24.

Black masterbatch, conductive compounds, graphene enhancement

Hubron is showcasing black masterbatch formulations and additives, conductive compound innovations, graphene-enhanced technologies, and more.

At K 2025, its focus is to upfront the role of masterbatch formulations in reducing addition rates, improving dispersion quality, and minimizing equipment downtime. Technical director Rob Laurent emphasizes that these considerations help manufacturers “achieve the same performance with less material, which directly impacts both costs and environmental footprint.”

According to Hubron, these formulations can be used to meet the growing demands for sustainability as regulations tighten, as well as overcome cost constraints and minimize equipment downtime.

Laurent adds that “black masterbatch is the essential final ingredient for perfecting performance, whatever the plastic application.”

The company’s personalized approach is set to help customers tackle their individual problems more effectively than off-the-shelf alternatives.

Visitors are invited to consult Hubron’s staff about personalized solutions and compliance requirements for specific industrial applications. Meetings can be scheduled via Hubron’s website.

Find out more at Hubron’s booth – go to Hall 5, Stand A39.

Palletizing flexible pipes with automated machinery from FB Balzanelli

At this year’s show, FB Balzanelli presents automatic palletizing systems for its flexible pipe products. These advanced systems utilize automatic strapping and wrapping solutions for pallets, coils, and bars, alongside robotic arms, collaborative robots, or Cartesian axes.

Each of its systems is developed through co-design processes with customers, which is hoped to facilitate full compatibility with existing setups and allow easy integration into both new and upgraded lines.

Automating these processes is anticipated to improve production flow, with FB Balzanelli aiming to keep productivity high and long-term operational costs low in a competitive market.

At the same time, keeping operators away from repetitive and/or high-risk tasks is expected to benefit both morale and safety, directing employee labour towards more valuable jobs in the warehouse.

To find out more, visit FB Balzanelli at Booth A60 in Hall 16.

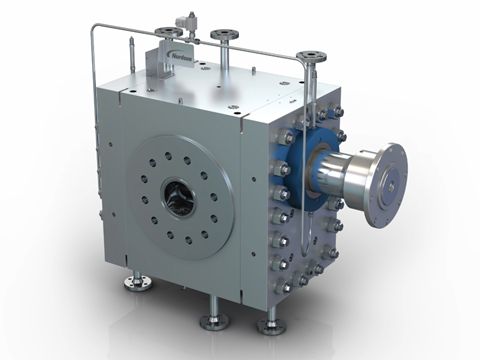

Polymer melt pumps from Nordson BKG tackle polymer shear and more

Nordson BKG has launched its PolyNeo Melt Pumps, engineered with advanced heating technology. By optimizing heating and flow dynamics, the company aspires to maximize output – claiming to support throughputs of up to 20 tons per hour.

Reportedly, the simplified design of the pumps keeps downtime and service complexity at a minimum. At the same time, the final product is believed to provide ‘superior’ thermal control, high precision, and consistency across a range of applications.

Notably, the pumps are designed to overcome challenges related to polymer shear. They are intended to achieve smoother flow, improved material integrity, and higher product quality overall.

Nordson aspires to meet the ever-higher demands of polymer processing without impacting quality. It aims to reduce material waste and defects, lower energy consumption and operational costs, and support advanced formulations with minimal variability.

See Nordson BKG’s stand in Hall 9, Booth D09 to find out more about this product range.

Revealing Omya’s polymer distribution services at K 2025

Omya Performance Polymer Distribution has made its official debut at K 2025. Following the strategic acquisition of Distrupol and the integration of Omya’s existing polymer distribution network, the new business aspires for a ‘more agile, customer-centric approach to polymer distribution’.

The company’s portfolio features polyamide, polycarbonate, ABS, polyethylene, polypropylene, TPU, elastomers, PBT, acrylic, and acetal from various producers – yet it emphasizes that more options are available. It also provides support in material selection, design consultation, and application development advice, as well as its performance polymer portfolio and global supply partnerships.

At its K Show booth, visitors can learn more about the company’s product offerings and inquire about tailored solutions across industry applications, including packaging.

Attendees can also see Omya’s advanced calcium carbonate solutions, including pre-consumer recyclate grades like Omyaloop FC and Omya Smartfill 55-AV; developments in its Omyafilm lineup for thinner film production; and specialty materials like biobased additives and CO2-reducing solutions, developed in collaboration with leading manufacturers.

Visit Omya at Stand D75 in Hall 6 to find out more.

Co-creation and circularity with Kuraray

We’re at K with Didier Houssier, Market Development Director EVAL to learn about the solutions and themes that Kuraray is exhibiting at the show. Take a look!

Lindner and Procter & Gamble launch mechanical recycling innovation Flexloop

At the centre of the “revolutionary” mechanical recycling technology launched at K is a solvent-based extraction process which reportedly removes impurities (NIAS), odours, adhesives and printing inks from polymer chains.

The achieved purity level is said to open up new application options, allowing post-consumer recyclate to be used for sensitive packaging in the cosmetic and personal care sectors.

The origins of this development go back to the last K show, where first discussions were held between Lindner and Procter & Gamble. Eventually, Lindner obtained exclusive licensing rights to the technology developed by Procter & Gamble, with the mutually agreed goal of establishing an industrially scalable recycling process.

“We have always wanted to advance mechanical recycling,” said Michael Lackner, CEO of Lindner Group. “For us, Flexloop is a logical and necessary development in mechanical recycling and an extension of cold and hot washing.”

Lee Ellen Drechsler, Senior Vice President of R&D at P&G, added: “We can foresee a growing demand for high-quality recycled resin that is suitable for a wide range of flexible film applications, so we are excited for the introduction of Flexloop, an innovation our researchers developed as an option for upcycling a wide range of plastic materials through mechanical solvent extraction. The licence of this plastic-to-plastic cleaning technology to Lindner is consistent with our corporate commitment to bring to scale technologies that can help address significant environmental challenges including the reduction of plastic waste and achieving a circular economy for materials.”

“The difficulty of obtaining high-quality, clean recyclate is a particular problem when handling post-consumer waste and for mixed plastics from domestic and commercial collections,” said Yannick Stanau, Business Development Manager at Lindner Washtec.

“During collection, plastics of all different types and origins are mixed together, and they can absorb substances that you wouldn’t expect to find in this material. For example, food packaging could come into direct contact during collection with packaging that was not originally intended for food – NIAS can diffuse into the polymer and be transferred. With Flexloop, we have found a solution for this problem. It can be viewed as an extension of the mechanical recycling process. The additional solvent-based cleaning step makes it possible to extract NIAS, odours, adhesives and printing inks out of polymers, without attacking their structure. Recyclates obtained this way not only comply with legal requirements, they also meet the often much stricter specifications of many brand manufacturers.”

Gian De Belder, Technical Director, Packaging Sustainability at P&G, pointed out that Flexloop was particularly important for a wide range of feedstocks, specifically packaging and agricultural films.

“The technology allows us to get a step closer to make film packaging fully circular by closing the loop, for example by producing high-quality rPE film grades that can safely be used in a new generation of film packaging aimed at sensitive packaging applications.”

Sirmax Group at K 2025: plastics solutions and injection moulding techniques workshop

Sirmax Group is due to present a variety of compound products and host a workshop focused on new injection moulding techniques for compounds containing post-consumer recycled (PCR) materials.

Located at 8B, Stand C69, Sirmax’s portfolio at the show will include various compounds: polypropylene (unfilled, additivated, fibre-reinforced or modified); high-performance technopolymers (styrenic, technical, special and blends), marketed under the Iso and Dafne brands; Xelter thermoplastic elastomers, an alternative to vulcanised rubber; and Biocomposites and Green versions of all lines, with variable post-consumer or post-industrial recycled content. Each material is designed to guarantee ‘high performance, versatility and sustainability’, with applications ranging from automotive to construction, electronics to packaging and sports to leisure.

Alongside the traditional sectors of automotive and household appliances, the Group has invested over €3 million to new facilities, laboratories and specialized resources focused on the electrics and electronics sectors. Sirmax says UL94 and RTI certifications are underway, in line with the requirements of international customers.

Workshop: “Molding the future – optimizing processes with green compounds”

Scheduled for the 9th October, 5 p.m at the company stand, Sirmax will hold a workshop in collaboration with Smart Mold – a spin-off of the University of Padua, 50% owned by Sirmax - dedicated to new injection molding techniques for compounds containing post-consumer recycled materials. The companies are due to present advanced simulation software and methodologies seeking to reduce waste and product weight, especially the patented GAPP (Gas-Assisted Push Pull) technology, designed to eliminate the effect of weld lines in plastic parts, improving both their strength and aesthetic appearance.

Sukano to showcase BOPLA masterbatch and additive technology at K 2025

Sukano is due to present its BOPLA masterbatch technology and additive technology at K 2025, designed to enable barrier properties for compostable packaging and production of recyclable PET closures.

In collaboration with NatureWorks, Sukano has developed a compostable plastic packaging solution designed to address challenges such as limited processability, poor barrier performance and high investment costs. The companies have created a masterbatch and a tailored biobased material, said to enable scalable production when used together, to support the transition from fossil-based plastics to compostable materials.

Sukano says the newly developed SUKANO Antiblock masterbatch enhances the performance of NatureWork’s Ingeo Extend 4950D, enabling efficient processing of biaxiallyoriented PLA (BOPLA) films on existing BOPP equipment. This allows customers to produce high-performance, compostable films with up to 7x transverse direction stretch, offering smoother processing, ‘excellent’ printability and enhanced optical properties.

The company adds that the masterbatch increases surface roughness in the inner layer, preventing the film from sticking during winding and secondary processing. In the outer layer, the masterbatch helps create a smooth and uniform surface to obtain a continuous layer of aluminium with strong adhesion, resulting in fewer defects in the metal coating.

Sukano’s new additive masterbatch range allows the production of monomaterial PET or rPET caps that can be recycled with the bottle, eliminating the need to separate caps from bottles during recycling. According to Sukano, with caps comprising up to 10% of bottle weight, this unlocks a ‘thousand tonnes’ of additional bottle-grade PET for circular reuse.

The additive package is compatible with both thermoforming and injection moulding processes, enabling customers to transition to mono-material bottle solutions without changing their existing production setup.

Borealis debuts reusable cups made from recycled OMV feedstock at K 2025

At K 2025, Borealis will distribute a deposit-free reuse system for cups made from modified polypropylene for foam, utilizing chemically recycled feedstock from OMV’s ReOil technology.

This is believed to be the first time the Messe Düsseldorf exhibition centre will offer a comprehensive system for reusable cups, which will operate at every restaurant and bar serving drinks at this year’s K Fair. You can find out more here.

TotalEnergies and SML target material savings with new downgauging film solutions

TotalEnergies and SML have partnered to develop two films said to enable ‘substantial’ material savings in stand-up pouch and deep-freeze bag applications through efficient downgauging, due to be unveiled at K 2025.

Made with TotalEnergies’ Lumicene Supertough, both films are apparently fully recyclable and suitable for existing recycling streams. The two films will be exhibited at K 2025 in Düsseldorf from October 8th-15th, at TotalEnergies stand E20, Hall 6 and SML stand C39-42, Hall 17. Read more about these applications here.

PiovanGroup: Integrating Global Innovation

PiovanGroup is a global leader of process-automation systems for polymers, bio-resins and recycled plastics, as well as for food & beverage ingredients (liquids and powders).

With a production footprint, R&D centres, and subsidiaries located around the world, the group delivers technical and commercial support wherever polymer processors and brand owners operate. Integrated processes spanning R&D, engineering, supply chain, project management, and service enable the group to identify market needs globally and turn them into ready-to-use solutions available worldwide. These solutions ensure superior quality, traceability, stability and process continuity even when working with advanced techno-polymers, controlled environments or growing amounts of recycled content.

What’s new at the show

- SmartForesight: a predictive maintenance solution that detects anomalies before failures occur. With real-time notifications, customized reports, and direct technical support, the service maximizes customers’ profitable uptime.

- VOC Minder: an inline tool for monitoring volatile organic compounds in processes using recycled materials, ensuring quality compliance and reducing waste.

- Permanent Vacuum: a complete material distribution solution built around a single vacuum line, parallel modular pumps, central filtration, and a dedicated coupling station, Multilink, that automatically sets up source-to-destination connections. It maintains a constant vacuum, optimizes investments and system resilience, enables simultaneous conveying and modulates pumps to match demand—increasing efficiency.

- GN³: top-notch three-stage system based on the GenesysNext platform for gentle dehumidification that completes cycles in just 5 hours while preserving optimal material integrity. Enables rapid resin changeovers within 2.5 hours, a 68% reduction versus conventional systems, boosting operational continuity and flexibility.

- Quantum Med: a compact, hygienic gravimetric dosing solution for medical environments, featuring quick changeover and materials compliant with the industry’s demanding standards (GMPs).

- Downstream Extrusion: Precision-engineered solutions for the medical industry, featuring the MedVac® Vacuum Sizing Tank and MedLine® Puller/Cutter with servo-controlled cutting accuracy (±0.1 ms). Built on the market’s extensive experience in medical extrusion, these products ensure maximum performance.

- Grado Adroit 8: a batch gravimetric blender with integrated extrusion control handling up to 8 components. Thanks to its fully modular architecture, users can independently change the number of ingredients at any time.

- Vento: an automatic film cooling and thickness control system based on a triple-flow ring that delivers a threefold effect—cooling, stability, and control. “Double chimney” and “lifting system” options further boost line productivity.

- GDS9-2000: a new high-throughput gravimetric feeder (up to 2,000 kg/h) designed to precisely handle pellets, regrind, and powders—even in complex extrusion and compounding plants.

- AryaDew: an innovative mold-enclosure dehumidification system with closed-loop technology that delivers up to 70% energy savings and stable processing conditions.

- PETChiller+: a new PET mold-cooling system that cuts cycle times by up to 30% and optimizes energy consumption with modulating compressors and inverter-driven pumps.

Why visit Booth C20

Real solutions for concrete needs:

- Enhance productivity, quality and sustainability of the process while maximizing energy efficiency;

- Clear impact metrics (cycle times, energy, OEE);

- Modularity and scalability for both new lines and retrofits.

- Direct dialogue with the people who design, integrate, and service systems—from the shop floor to the cloud.

- Digital services (connectivity, energy audits, predictive maintenance, traceability, etc.) for operational excellence and sustainability.

An experience built around sectors and solutions

The exhibit is organized into dedicated areas for technical components and automotive, medical and pharmaceutical, rigid and flexible packaging, fiber, strap, profiles, and tubes, compounding, recycling, PET/rPET preforms and bottles, and heat transfer—covering nearly 500 m² of technologies. Specialists will be on hand and visitors can explore the group’s system solutions with virtual reality experiences.

The Group’s Piovan, Conair, Doteco, Pelletron, Piovan Fdm, Piovan Food&Powders, Piovan UnaDyn, and Thermal Care will be present at K 2025.

“Integrating global innovation means bringing technologies and services directly into production, immediately reducing cycle times, energy consumption, and errors while ensuring high quality standards, even with increasingly complex materials. We invite processors and brand owners to visit our booth and discover how much value they can unlock in their processes,” says Felice Meliti, Chief Commercial Officer, PiovanGroup.

Find PiovanGroup at K 2025 on stand C20 in hall 10.

This article was sponsored by PiovanGroup.

Coim targets recyclability and production optimisation

Chemical specialties company Coim will be presenting its solutions including RecyClass approved adhesives, polyurethane-based inks and cold seal coatings at K 2025.

Coim says its portfolio at K will include five RecyClass approved adhesives; polyurethane-based inks for high-performance sectors such as packaging for aggressive materials and complex thermal cycles; and cold seal coatings for food and non-food applications such as ice cream and chocolate, said to offer high performance and easy application on various substrates. Also on display will be Coim’s TPU and hot cast elastomers for high-performance applications.

Click here to read more.

Kiefel showcases innovation for rPET, fibre and more

Kiefel is positioning itself at the K trade fair 2025 as a driver of innovation in industrial manufacturing. In Hall 3 / D90, the specialist for thermoforming and joining technologies will impress with a broad portfolio for the packaging, medical and pharmaceutical, appliance and service sectors – and will add special focal points with two technology solutions. The company will present new product developments, including the thermoforming machine SPEEDFORMER KTR 6.2 Speed and fibre packaging innovation.

Click here to read more.

ExxonMobil collaborates with value chain partners to showcase PE and PCR solutions

ExxonMobil will be showcasing its polymer solutions at K 2025, including product samples, film rolls and the option to interact with solutions from industries such as agriculture, healthcare and consumer products during guided tours.

The company will be displaying its solutions at the ExxonMobil Pavilion FG04.3 outside Hall 4. ExxonMobil says multiple solutions were created in collaboration with machine manufacturers, converters, and brand owners, such as its mono-material PE solutions designed for recyclability and/or downgauging opportunities like the MDO cereal pouches from Colines, freezer pouches from W&H, silo bags from Armando Alvarez, pet food bags from Bandera and vacuum skin cheese packaging from Alpine.

Click here to read more.

Frigel to present new temperature control and cooling solutions at K 2025

Frigel has announced it is due to present its new DYNAMICO temperature control technology and HVM modular chiller system at K 2025, designed to reduce energy costs and provide operational flexibility.

Directly replacing conventional temperature controllers in any existing mould, the company says that the cycle cooling time reduction obtained with DYNAMICO can lead to productivity increases of 20% to 50%. Frigel adds that in polyolefin moulding, installing DYNAMICO between the existing cooling system and the mould has demonstrated productivity gains of 10% to 25%.

Click here to read more.

Vioneo to debut fossil-free PE and PP solutions at K 2025

Vioneo has announced it will be debuting at K 2025 with its fossil-free polyethylene and polypropylene solutions, said to reduce CO2 emissions.

Vioneo says its Antwerp-based plant is designed to deliver these ‘commercially ready’ materials at scale, ensuring quality while delivering significant environmental benefits. The company claims that for every kilogram of plastic produced, up to 6kg of CO2 emissions are avoided.

Click here to read more.

Sirmax Group at K 2025: plastics solutions and injection moulding techniques workshop

No comments yet