To align the industry’s drive for higher performance with the increasing customer demand for sustainable solutions, the market needs to consider different packaging concepts and materials for laminates and hot drinks products. Plastics derived from renewable biomass (plant material), such as PBS, are rising to the challenge - write Fabien Resweber (PTTMCC Biochem) and Lawrence Theunissen (Reverdia)

The highest priority should be to reduce, re-use or recycle packaging materials. In specific cases where recycling is not technically or economically possible, solutions are being developed based on compostable materials, including paper, cardboard and also compostable plastics. While PLA is probably the most widely known compostable plastic, other materials like PBS (poly-butylene-succinate) and PBS-copolyesters are being increasingly used.

Compostability, or biodegradability, can be described as a material’s ability to be converted into CO2 and water, by breaking down into smaller parts that are then consumed by microorganisms. This means that compostable materials produced from plant biomass can fit into a more circular economy if they are safely returned to the environment.

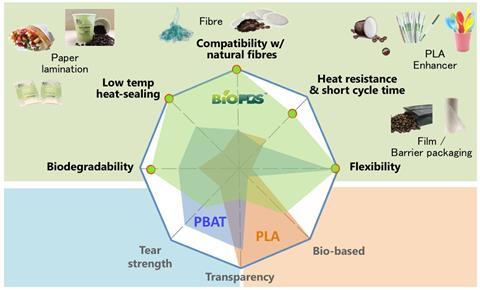

PBS has been on the market since the early 1990s and since then has been used in many compostable products, such as mulch film, waste bags, laminated paper, plant pots and many more. PBS offers attractive general physical properties, such as high flexibility, good impact and heat resistance. PBS is also easy to process at high extrusion speeds, has short moulding cycles, does not require pre-treatment before printing and is approved for food contact. It is therefore unsurprising that PBS is enjoying increasing popularity as a sustainable packaging material.

The PBS polymer is produced using 1,4-butanediol and succinic acid as raw materials. Originally, both monomers had to be produced from fossil resources. Supply chains have recently seen an increase in the use of renewable raw materials to manufacture bio-based alternatives. While technologies for bio-based 1,4-butanediol are in the early stages of commercialisation, 100% bio-based succinic acid has been commercially available from Reverdia since 2012. Such bio-based raw materials can be produced from different types of abundantly available, locally grown biomass, such as starch crops, lignocellulosic residues, sugar cane or wood residues. Also, they help to reduce global warming by being carbon neutral; the renewable carbon captured within such bio-based raw materials is extracted from the atmosphere by the biomass.

Since 2015, PTTMCC – the world’s largest PBS producer – has been using bio-based succinic acid exclusively for its BioPBSTM brand. Its BioPBS grades range in bio-based content from 35% up to 50%, making BioPBS an attractive option for sustainable flexible packaging, due to its bio-based content and compostability.

Introducing a third monomer during PBS production leads to PBS copolyesters such PBSA or PBST. Such grades have slightly different properties, such as more flexibility and transparency, which can be relevant in specific applications. PBS is often compounded with other polymers, fillers and/or additives in order to further optimise the property profile.

PBS offers advantages for many products that are notoriously hard to recycle because of their heavy contamination, multi-material composition, etc. For instance, in multi-layer, extruded films or laminates, each polymer layer has its own function such as protection, barrier, sealing, etc. Such multi-layer materials offer many performance advantages, though when it comes to end-of-life, disposal is often difficult. Difficulties in separating the different materials generally prevents efficient recycling. For this reason, high-performance compostable laminates have been developed, using bio-based PBSA which demonstrates excellent sealing performance and is ideal for the seal-layer of such environmentally-friendly packages.

In applications ranging from packaging boxes to coffee cups, paper or cardboard surfaces are often laminated with PE to act as a barrier layer against moisture. When this PE is replaced with PBS, the paper retains the same recycling properties provided by PE, but can additionally be completely composted.

Another example is single-serve coffee capsules. These capsules represent a fast-growing market, with billions of units produced annually. The coffee capsules sold by one major brand in 2013 alone created enough waste to wrap over the earth more than 10 times! The high fraction of water and coffee grounds makes them difficult to incinerate or recycle, but this waste problem can be easily prevented when using compostable capsules based on BioPBS.

Previous versions of compostable capsules had a limited oxygen barrier, requiring a secondary packaging for wrapping. New solutions for compostable oxygen barriers now exist for all coffee capsules designs, decreasing the total amount of packaging needed. As industrial composting facilities are not yet widely implemented worldwide, home-compostable coffee capsules are expected to come to market very soon and will simplify disposal for users.

In summary, the easy processing of PBS, combined with an attractive set of physical properties, makes it a great candidate for a range of high-performance packaging solutions and the use of bio-based raw materials boosts products’ sustainability. Finally, in applications where it is impossible to re-use or recycle, compostable materials may contribute to cleaner end-of-life options and lower disposal costs.