Keiryo Packaging technology for plastic processing integrates molecular ordering into the polymer melt, triggering “flow-enhanced morphological changes” in the polymer mass with the aim of enhancing material functionality. The company says that this ‘KP Technology’ is applicable across various conversion technologies and for both amorphous and semi-crystalline polymers used in finished plastic articles.

We asked the company’s co-founder and member of the board Tangui Van der Elst and Dr Edyta Niemczyk (PhD), engineering team lead, about the details behind the technology, how it aims to improve the quality of packaging, and the results of its recent trials with free blow PET bottles.

To start with, could you summarise what you do in a few sentences?

Tangui Van der Elst: Our mission is to improve the performance of plastic materials by simply altering their morphology during the processing phase, without incorporating any additives. By achieving this the Keiryo technology reduces both the environmental footprint and manufacturing cost of polymer-based packaging articles.

Keiryo, meaning ’less weight’, is the core concept behind what the patented Keiryo Packaging Technology delivers. Based on polymer science, the KP Technology triggers a phenomenon called Flow-Enhanced Nucleation and Induced Crystallisation (FENIC). FENIC utilises flow as a driving vehicle for the creation of ordered entities (that can be crystals). In turn, these ordered entities greatly enhance the overall material functionality, barrier for example. As a result, less material is required to provide a similar performance to the plastic article.

The KP Technology is applicable across various processing technologies: (ISBM) [Injection Stretch Blow Moulding]; direct injection; extrusion for semi-crystallines (such as PET and PP) polymers which are used in finished plastic articles. The technology can be applied to virgin, recycled, or mixed material derived from bio or fossil sources.

To be truly impactful any technology needs to be scalable. Our background in the FMCG industry taught us that the best way to reach scale was to leverage existing infrastructure and avoid adding complexity. We achieve this by having a technology that can be retrofitted into existing machinery like a spare part and that focuses on material efficiency.

You say that your technology helps to produce plastic packaging using less material, more recycled material, and better barrier performance. How is this achieved?

Dr Edyta Niemczyk: The performance of polymers is defined by their morphology – its altering can unlock additional functionalities of the final material. The ability to change its morphology of any semi-crystallisable polymer (virgin, recycled or composition thereof derived from bio or fossil sources), is possible while utilising the previously mentioned phenomenon called FENIC.

This phenomenon describes a shift of the morphological balance from amorphous to the ordered entities (nuclei and/or crystals) by leveraging existing flow. Higher level of order of the molecules can be advantageous for barrier applications – the ordered morphologies can act as an obstacle that delays the gasses permeation.

You have developed a 3D printed insert added to the existing injection process. How does this impact the quality of the packaging being produced?

Dr Niemczyk: Changes in the morphology are realised through a designed combination of shear-based and extensional-based forces. [Explanation provided by Van der Elst: take the example of a rubber band. If you stretch a rubber band extensional forces imply its elongation. On the contrary, if you laid the rubber band on a flat surface and slid your hand over it, the shearing forces would entail its shape change.

During the flow of the molten polymer, in the injection moulding or extrusion process, both of those forces are present. Shear forces are maximised at the wall and minimised in the center of the polymer flow. Extensional forces are maximised in the center of the polymer flow and are minimised at the wall.]

All of those forces are present in the processing machinery, whenever the polymeric flow is present (ISBM, direct injection, extrusion) – what the KP technology does is amplify those forces.

It is important to mention that said amplification of the shear-based and extensional-based forces does not harm the material nor lead to its degradation.

To optimally leverage the flow, our technology combines a software and a hardware component. The initial magic happens at the software level. Keiryo developed a modelling tool defining the deformational flows that influence the morphology of the polymer. Based on this data, we design the 3D printed insert – the physical component of our technology, that is retrofitted on standard injection machinery.

The inside of the insert is made of microchannels generating a well-defined friction when the polymer passes through the hot runner into the preform mould. This generates morphological changes in the polymer that improve its performance.

On your website, you mention molecular dynamics and deformational flow. What does this mean exactly, and how does it relate to packaging?

Dr Niemczyk: Deformation flow is composed out of the shear-based and extensional-based forces. It implies an alteration in the ordering of the molecules and happens to the molten polymer in a limited manner in every ISBM, direct injection, extrusion process.

Depending on the strength of the deformational flow, the molecules can respond accordingly by stretching and forming so-called ordered entities (that can be crystals). This response is molecular dynamics.

Currently in the industry, molecular dynamics are not leveraged. However, if intentionally applied above the threshold stress level, flow-induced ordered entities are created and remain stable after the flow has ceased - even at conditions above the equilibrium melt temperature!

At the moment, Keiryo focuses on the Injection Stretch Blow Moulding of PET bottles but the underlying science and the technology we develop applies itself to different polymers, fossil and biobased as well as different processing techniques.

More specifically, your website also mentions the use of Flow Enhanced Nucleation and Induced Crystallisation (FENIC) in your technology. What does this mean, and how does it work in practice?

Dr Niemczyk: The combination of molecular dynamics and deformational flows are driving the FENIC phenomenon. The KP software quantifies the deformational flow that needs to be applied to shift the balance of the molecular dynamics towards increased ordered entities formation: starting with the nucleation and the end goal being crystallisation.

The crystals formed in this way are different from those created through quiescent crystallisation. FENIC allows the formation of smaller and homogeneously spread entities in the bulk morphologies.

I understand you recently conducted free blow trials of PET bottles, with a change in performance between those with Keiryo Packaging Technology and those without. Could you tell us more about this, and what it might mean for future packaging processes?

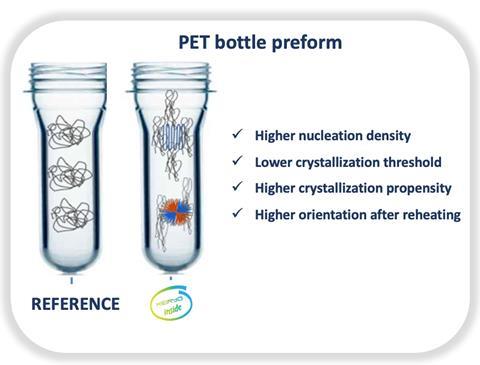

Van der Elst: We are running trials in the industrial facility of our technology partner PDG Plastiques. These trials are done on standard machines using regular grade resin like those used to manufacture PET bottles you find in your supermarket. The preforms produced with Keiryo inserts have a different morphological structure: they show higher nucleation density.

The bottles made of these Keiryo inserts based preforms are also different. We are still in the process of fully scoping these differences, but the demonstration that morphological changes are carried over in the bottle is an important milestone.

Given that these results were achieved in an industrial production facility using standard machinery and commercial grade resin, it bodes well for the global scalability of Keiryo’s technology.

Your mission is to improve materials performance and enhance the economic and environmental sustainability of packaging articles. How does your technology help to achieve this aim?

Van der Elst: When we think of plastic sustainability what springs to mind are solutions like better recycling, more efficient waste management systems and developing new, non-fossil-based materials. Material efficiency tends to be overlooked whilst it can be an important contributor to a more sustainable, circular use of plastics.

With materials efficiency, environmental sustainability and financial savings tend to go hand in hand. Specifically, in our case improving plastics’ performance will allow us to use less plastic per bottle, render PCR plastic more usable and reduce the use of additives that enhance efficiency but are harder to recycle.

If you look at the benefits of material reduction, you will notice that they cascade. First, if you extract less raw materials, you use less energy, yielding cost savings and reducing CO2 emissions. Second, it will also limit the volume of waste which influences EPR costs. Third, if you reduce the amount of waste produced, you also reduce the amount of waste leakage in nature.

These benefits increase with the adoption rate. That is why it is important to have a solution which is easily scalable, which is the case with Keiryo.

What goals would you like to see the company achieve in future?

Van der Elst: Today our focus is on developing our solution for PET ISBM, but we know that it can be applied to other polymers and manufacturing processes. For PET ISBM applications we have signed pre-commercial agreements with large FMCGs and are looking to replicate this model with others.

The first steps towards branching out into polyolefins are well under way. We have also had several conversations with producers of biomaterials who see our technology as a means to address functional performance challenges.

Because our technology is inherently highly scalable, it can be a big contributor to a world with more sustainable packaging.

Keiryo Packaging was a finalist in our Sustainability Awards 2022 with its polymer processing technology. This year’s Sustainability Awards winners will be announced at the Sustainable Packaging Summit in Amsterdam in November, and you can find out more here.

No comments yet