According to research by the SAVE FOOD initiative, around one third of food produced for human consumption every year worldwide - approximately 1.3 billion tonnes - is wasted.

In industrialized countries, more than 40% of losses happen at retail and consumer levels. Food is sometimes thrown away ‘just in case’ when it is still fine to consume. Active freshness can give consumers useful information about the freshness of the food they are buying or have bought. Elisabeth Skoda explores various innovations in the field, ranging from colour changing labels, to tags that link up with smartphones to give detailed information, and sensors that indicate how ripe fruit is.

According to Dr. Graham Skinner, product development manager at Insignia Technologies Ltd, there are two main challenges in the fight against food waste: Poor chill chain management within the supply chain and uncertainty about how long ago food packs were opened after purchase. The company has developed tags that help retailers and the restaurant industry address this issue.

Colour-changing tags

The company’s FreshTags are colour changing TTIs (time-temperature indicators) which can be applied at point of manufacture, then stay with the product throughout the supply chain.

“If the product has been kept within the recommended storage temperature range, the label will change colour in line with the expected shelf-life of the product. However, products are often temperature abused due to sub-standard refrigeration units or poor chill chain management, such as leaving refrigerated truck doors open. This results in a lower quality product by the time it gets to the restaurant. Insignia’s FreshTag labels will change colour faster if food has been temperature abused, which allows the restaurant to prioritise those products.”

Insignia’s customers have observed significant positive behavioural change of staff maintaining the chill chain when the FreshTags have been utilised.

“The overall impact of this behavioural change has led to fresher, better quality produce, a significant reduction in product rejections and a reduction of food waste,” says Dr. Skinner.

He points out that Insignia also offer after opening/secondary shelf life timers for consumers, which automatically start to change colour once a pack has been opened, allowing the consumer to make more informed decisions on the freshness of the food after opening.

“When the pack is opened, the atmosphere around the label changes, triggering the colour changing process, and the centre dot changes colour from yellow to purple as the food becomes less fresh. This gives a clear indication of how long the pack has been opened.”

Monitoring carbon dioxide

Insignia’s patented intelligent smart pigments and plastics are formulated to change colour when there is a change of carbon dioxide levels in modified atmosphere packaging.

“The intelligent label is embedded in the inside layer of the lidding film of a modified atmosphere package or bag. When the package is flushed with CO2, the label turns yellow but remains the same colour until the package is opened, releasing the CO2. Once the package is opened the label begins timing, responding with a colour change that can be pre-set. The colour change response is faster in higher temperatures, aligning the label with actual product freshness. The colour changes are reversible, and we can also alter the chemical formulation of the pigments to produce a wide variety of indicators with different sensing properties. There is a colour chart next to the sensor so consumers can be sure what colour to look out for,” Dr. Skinner adds.

Eating fruit and vegetables when they are ‘just right’

Knowing when the best time is to eat a piece of fruit can be tricky and can involve a lot of guesswork that could result in food waste. ILIP's Smart Ripe addresses this issue by providing real-time information on the ripeness of fruit.

Developed in collaboration with Radio6ense, a spin-off of the University of Rome Tor Vergata, and with the University of Turin’s Department of Agricultural, Forest and Food Sciences, it works thanks to a sensitive sensorized RFID tag that is integrated within the packaging, which can detect certain dielectric variations in the fruit pulp associated with ripeness, such as turgidity, acidity as well as water and sugar content.

This information is transmitted to a terminal that can be programmed to return the desired information, ranging from a simple indication of whether or not the fruit is ripe, to advice on how or when to use it. In the case of avocados, the first product on which Smart Ripe was successfully tested, data can be obtained regarding consumption times (‘not yet ripe’, ‘ready to eat’, ‘creamy’) or methods of use (‘for cooking’, ‘for salads’, ‘for sauces’, etc.).

Currently, the technology has been designed for ‘premium’ fruit and vegetable products, such as avocado, mango and papaya, however, the principle can be applied to different types of fruit or vegetables, as Luigi Caravaglia, R&D manager at ILIP, points out.

“Smart Ripe is a technology that can monitor – in real-time and in a non-invasive way – the freshness and ripeness of a fresh product. With this innovation, we are paving the way to numerous applications that will improve handling of fruit and vegetables at the point of sale and the consumer purchase experience.”

Monitoring meat and fish with paper-based tags

Back in the UK, academics at the Imperial College London have developed paper-based, smartphone-linked spoilage sensors for meat and fish packaging. The researchers say the new sensors, made by printing carbon electrodes onto cellulose paper, could help detect spoilage and reduce food waste for supermarkets and consumers.

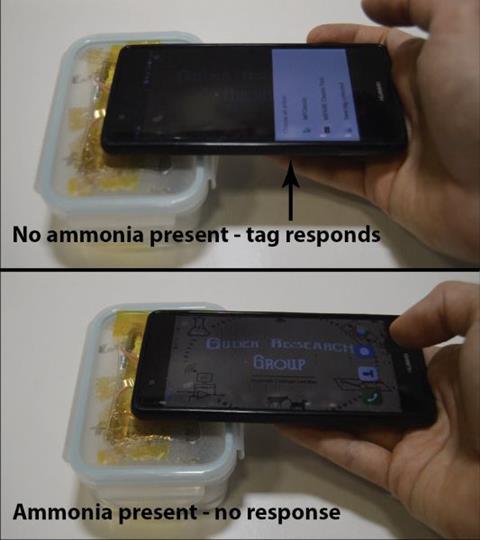

Dr Firat Güder and Giandrin Barandun from the Department of Bioengineering at the Imperial College London explain the benefits of these new laboratory prototype sensors which are known as ‘paper-based electrical gas sensors’ (PEGS) and are designed to detect spoilage gases like ammonia and trimethylamine in meat and fish products.

“Many freshness sensors already on the market rely on chemical reactions that lead to a colour change. However, judging a colour change is a subjective measure. Our sensor gives an electrical signal which can easily be used in digital data processing. The RFID tags into which the sensors will be integrated in are already used in packages for many different foods and other goods, for example for security or information purposes. This makes it very easy to add our sensors to the packaging process. Our sensor is also suitable for very humid environments.”

Powered by NFC

The tags are powered wirelessly by the smartphone once it comes close, i.e less than ten centimetres, to the tag, enabling the smartphone and the tag to communicate, as Dr. Gürer explains.

“This technology, near-field-communication (NFC) is already commonly used for contactless payments or public transport, such as on the Oyster card in London.”

The researchers say that the sensors integrate easily in existing RFID tags on packs, but that protecting the sensors is something that still needs to be looked at.

“The sensors should not get in contact with the food or any liquid, as this would alter the readings of the sensor. We are looking at ways to protect them by adding a gas permeable, waterproof layer to protect the sensor. Packaging manufacturers already use many layers of different plastics to optimize their packs for retailers’ needs.”

The sensors, which were manufactured in the lab for a cost of under £0.02, were tested with cod fillet and chicken breast.

“In general, they can detect all water-soluble gases but are most sensitive to ammonia (NH3) and trimethylamine. These are the nitrogenous products of protein decomposition by bacteria. That said, our sensors can be used with any food that is packed in a sealed atmosphere, where the relative humidity is over 50% and there are some nitrogenous compounds accumulating from bacterial activity. The materials are biodegradable and nontoxic, so they are safe to use in food packaging. We feel that they could eventually replace 'use -by' date,” says Mr. Barandun.

The scientists used ballpoint pens and robotic cutters to create the first prototype sensors and believe in its scalability.

Dr Güder concludes: “We believe our simple technique could easily be scaled up to produce PEGS on a mass scale by using existing high-volume printing methods such as screen printing and roll-to-roll printing.”