In this edition of our ‘In Conversation With…’ series, Robatech’s product manager Small Units & Hot Melt Jetting Heads, André Laubacher, runs us through the ways its new Alpha adhesive melter series targets efficiency, flexibility, and lower energy consumption.

Can you give us a general introduction to Robatech’s new Alpha series? Why was it developed?

With the new Alpha adhesive melters, we are gradually replacing the Concept series, which has reached the end of its product life cycle.

In addition to design improvements for greater efficiency, lower energy consumption, and more flexible installation options, the Robatech Control System makes the biggest difference. The integrated, modern control platform enables easy system integration and control of adhesive application, but also offers a completely new user experience.

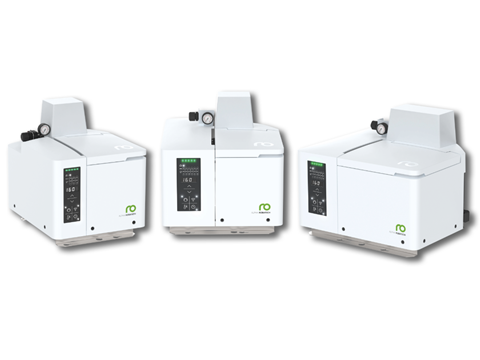

The Alpha series comprises three adhesive melter models: S, S Pro, and M Pro. Alpha S is already on the market, the first Pro versions will be delivered in November 2025.

What’s new in the Alpha lineup? How does it compare with previous Robatech series, especially in terms of performance and throughput?

The range of functions offered by the Alpha series is virtually identical to that of the Concept devices. It was important to us to retain the tried-and-tested functions, but also to incorporate new features.

Visually, the Alpha adhesive melters have a fresh, modern look. The Smart Terminal is in line with the spirit of the times: the most important status information is clearly visible even from a distance thanks to colored LEDs. In addition, the basic functions can be conveniently set on the Smart Terminal.

In terms of efficiency and economy, the Alpha series completely outshines the old generation of melting devices. Although the tank volume of Alpha is comparatively small at 4.1 or 6.8 liters, the melting rate is 8 kg/h or 12.5 kg/h. That is remarkable!

If we then consider the energy consumption, which is around 46% lower for Alpha than for the Concept series, we are providing our customers with noticeable improvements in industrial adhesive application.

Where did Robatech consider sustainability in the development of the Alpha series?

Alpha’s strength clearly lies in its low space requirements combined with high melt rate and reduced energy consumption, as I just mentioned. However, we have also focused on the supply chain. Our geographical proximity to our suppliers shortens delivery routes and delivery times. This not only benefits our ecological footprint.

Tell us about safety – how are these melters designed to protect operators?

CoolTouch protection is used as standard in our products. The FlexPort heated hose connection surface on the Alpha is also protected by CoolTouch.

In addition, we have enlarged the tank opening to make filling with thermoplastic adhesive more ergonomic and convenient. Of course, we have also equipped the tank opening with protection against burns caused by accidental contact. However, the automatic filling system for granule still offers the best occupational safety.

The adhesive is filled into a container far away from hot parts and conveyed to the adhesive melter. The necessary accessories are of course also available for the Alpha series. In the Pro versions, pneumatic pressure relief also ensures increased occupational and device safety.

Can customers integrate these melters straight into their production lines? Would it require any investments, redesigns, or extra training?

The Robatech Control System, with which the Alpha adhesive melters are equipped, allows connection to higher-level systems via standardized fieldbus systems and open interfaces. In the Pro versions, the adhesive application patterns are controlled via an integrated board. Customers who use electric heads can supply them with power and control them via the board. This is an interesting, cost-saving feature for machine builders.

When it comes to physical installation, the advantage of Alpha is that the adhesive melter can be positioned in a variety of space-saving ways thanks to FlexPort—the 45-degree connection surface for heated hoses. Since the heated hoses and application heads manufactured since 2000 are compatible with Alpha, Alpha is of course also suitable for plant modernization. Our service technicians support customers with simple measures to keep the effort to a minimum.

We always recommend training courses for operating and maintenance personnel, because well-trained staff who are familiar with the latest technical standards are the best guarantee for smooth adhesive application. In general, however, Alpha is very easy to operate because we have designed it to be intuitive and convenient.

By this I mean, for example, that the most important basic functions for adhesive application can be set at the touch of a button on the Smart Terminal. The pictograms are as self-explanatory as the standardized RobaVis user interface. This runs web-based on end devices, the host system, or the optional touch panel.

For the packaging industry specifically, what kinds of applications and customers would you recommend the Alpha series for?

Alpha is the all-rounder for packaging. We developed the adhesive melter with the specific aim of reliably covering virtually every packaging application. With up to six heated hose connections and the aforementioned melt rate, the Alpha series offers the necessary flexibility. In short: Alpha is the device of choice when it comes to the efficient melting and conveying of thermoplastic adhesives in packaging.

Click here to learn more about Robatech’s Alpha series.