Packing line solutions that protect the fragile nature of many fresh products and help producers meet the highest quality standards while also delivering high speeds and accuracy will be showcased on the Ishida Europe stand at Fruit Logistica 2019.

Highlights include two multihead weigher models specifically designed for weighing fresh fruit and vegetable produce, and the latest in Ishida x-ray inspection and checkweighing technology for enhanced quality checks.

The two multihead weighers on display demonstrate Ishida’s flexibility in dealing with the special characteristics of fresh produce. The Ishida 14-head CCW-RV multihead weigher - part of the company’s specialist Sector Solutions range that delivers optimum handling and accurate weighing of specific product types – can accommodate free-flowing, heavy products of variable piece sizes. Ideal for items such as larger citrus fruit or root vegetables, it features reduced discharge angles and drop distances to minimise bruising during product transfer.

The weigher delivers the RV’s reputation for unsurpassed accuracy and efficiency, while its unique triple combination calculation software can calculate three optimal weight combinations, double check them and then select the one nearest to the target weight - all in a single cycle. This minimises error discharges, increasing efficiency while also enhancing weighing accuracy and consistency.

The 6-head CCW-R2-106WB Fresh Food Weigher (FFW) is designed for all types of sticky fresh and bruise-sensitive products and smaller production batches. Product is typically delivered by a conveyor belt to the top of the weigher, where one or two operators then evenly distribute it via six belt feeders to the weigh hoppers. This ensures an even distribution, helping to increase both the speed and efficiency of the weighing process. Optional automatic feeding is also available. Features such as scraper hopper doors, ribbed surfaces and scraper gates on the collection belt conveyors minimise product sticking. Product giveaway is less than 1%.

To ensure maximum pack quality and safety, the Ishida IX-EN-2493 x-ray inspection system offers exceptional versatility in its ability to identify a wide range of foreign bodies in bulk or packed products, including stones, glass, metal and dense plastic and rubber. The machine is also able to carry out a number of other quality checks, such as spotting deformed products or packaging.

The IX-EN model offers an affordable but highly accurate entry-level solution, which incorporates Ishida’s patented Genetic Algorithm (GA) image processing software that is able to analyse image data over a number of generations to achieve a very high level of accuracy. Since many applications will require the detection of similar foreign bodies, the system can be optimised to look for these objects and help to eliminate recurring sources of contamination.

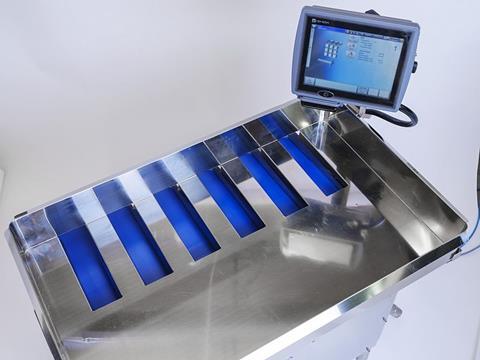

The DACS-G-060 checkweigher is capable of checking the weights of large packs and crates of fruit and vegetables up to 6kg. It features an Ishida designed, exceptionally fast and accurate digital load cell that is able to operate with great reliability in the harshest of environments. A unique feature of the load cell is its ability to switch between two weighing capacities and graduations, giving the DACS-G-060 the flexibility to switch between 3kg (1g graduation) and 6kg (2g graduation) for the handling of a large product range.

The DACS-G’s rounded stainless steel main body with open-frame design and quick-remove conveyor prevents bacteria traps and enables fast and thorough cleaning with reduced downtime. Importantly, unlike many checkweighers, the DACS-G’s vital measurement unit is protected during operation and cleaning by a special housing.

“The fresh produce sector is characterised by the variety of its products, but they share many of the same packing requirements, in particular the need for fast, accurate weighing with gentle handling,” comments Ian Atkinson, Ishida Europe’s Business Manager EMEA – Multihead Weighers. “Appearance is a crucial factor in a product’s selection by the consumer, and even the hardiest ones can suffer from bruising that makes them unappealing.

“The solutions on display at Fruit Logistica underline our ability to deliver both the highest product quality at the fastest throughput.”