In this article, our friends from CHINAPLAS look at the current state of the industry in light of COVID-19 and sustainability trends.

The coronavirus has only helped to underscore the importance of plastic packaging when it comes to keeping food contamination-free and to preserving its freshness and usability for longer. This is particularly vital now, given how millions of people worldwide are sheltering in place, and doing their best to make their provisions stretch.

But the COVID-19 pandemic has also accelerated another trend that has a major impact on product packaging -- e-commerce. Online shopping already was showing strong growth, but the current stay-at-home phenomenon has only increased demand. An even broader awakening to the convenience of delivery to your doorstep may forever reshape parts of the retail sector.

An April 4 story by DigitalCommerce360 cites data to underscore the current trends.

In North America, it reported, the number of online orders for web-only online retailers soared 52% year-over-year in the United States and Canada for the period of March 22 through April 4, according to an online tracker from marketing platform Emarsys and analytics platform GoodData. Revenue for web-only retailers in the U.S. and Canada was up 30% year-over-year for the period.

In the Asia-Pacific (APAC) region during the same two-week period, year-over-year transactions for web-only retailers grew by 23%, according to Emarsys/GoodData. During the same period, year-over-year revenue was up 19% in the region.

E-commerce growing sharply

Virus or not, retail e-commerce is rising sharply. New York-based consumer research firm Statista Inc. said that U.S. online retail sales of physical goods amounted to $365.2 billion in 2019, and projects that will rise to nearly $600 billion in 2024.

Consider also that China’s annual, 24-hour online shopping spree known as Single’s Day -- last held on Nov. 11, 2019 -- generated record sales estimated at some $38 billion.

The darker side of such a sales boom relates to the impact on the environment of so much product packaging. China’s State Post Bureau reported that e-commerce giants delivered 1.88 billion packages from Nov. 11 to Nov. 16 last year, an annual increase of almost 26%. Greenpeace estimated that the waste generated exceeded 250,000 tonnes.

The volume of packaging material used by China's e-commerce and express delivery sectors hit 9.4 million tonnes last year and is on course to more than quadruple to 41.3 million tonnes by 2025 if they keep up the rate of increase, according to Greenpeace and other non-government bodies.

Sustainability still important

So, booming e-commerce offers sales growth for key sectors as well as greater convenience (and safety) now for many, but it clearly comes at a cost. While public health trumps sustainability concerns at the moment, it’s clear that the packaging sector cannot afford to take its collective eye off the ball when it comes to being eco-conscious.

As Dow Inc. CEO Jim Fitterling mentioned in ANTEC 2020 virtual conference on March 31: The COVID-19 crisis is going to end, "but the air we breathe, our water and the land we live on is here forever. And we can't afford to lose the momentum that we've started to gain already to safeguard the environment and help us move to a more circular economy."

Leaders in the European Union also are concerned that the current virus-driven economic slump will cause the focus on sustainability to wane, writing in a joint statement in mid-April, “We should withstand the temptations of short-term solutions in response to the present crisis that risk locking the EU in a fossil fuel economy for decades to come.”

These conditions offer both extreme challenges and enormous opportunities for brand owners, consumer packaged goods (CPG) companies, and for those designing and manufacturing the packaging.

Multiple approaches being pursued

Such firms are exploring and advancing multiple strategies to address these issues, including increased plastics recycling, more reusable packaging, greater use of biomaterials, reduced material use, and design for circularity. Package designers also need to take into account the different priorities for on-shelf vs. e-commerce products. Eye-catching package design is less vital for products sold online than in the store, but ensuring the shipped product arrives at its destination undamaged is vital.

Advances in these areas take diverse forms, but consider the efforts being made by CPGs to redesign the e-commerce-friendly and highly popular –– but largely unrecyclable –– flexible pouches to make them more eco-friendly. This mostly involves finding a way to convert those pouches’ multilayer, multimaterial constructions, which till now have been needed to protect the contents from such unwelcome factors such as moisture, oxygen, and ultraviolet light, into recyclable, mono-material structures.

For example: mono-material pouches

Several advances are happening in this area. Austria’s Mondi Group, for just one example, worked with several partners for four years to develop an all-polyethylene, stand-up pouch for Germany’s Werner & Mertz GmbH to use with its Frosch-brand detergent. This patented pouch features detachable decorative panels on both sides, to help enable easier recycling.

Another new technology, called AeroFlexx and developed by Procter & Gamble Co., enables liquid packaging in a flexible yet rigid package. Made with coextruded flexible film, the product leverages compressed air to inflate specific portions of the pouch, specifically along the edges, to bring a degree of rigidity not otherwise possible in a flexible package.

An AeroFlexx package uses half the plastic needed to blow mold a traditional bottle and can be delivered as roll stock to a filling facility, meaning it is easier to ship throughout the supply chain. In addition to significantly reducing plastic at the source, the Chicago-based company’s vision is to be 100% recycle ready by 2025. While enabling seamless, edge-to-edge artwork, AeroFlexx also features a no-leak, self-sealing valve that offers easy, one-handed operation by the consumer.

An AeroFlexx package uses half the plastic needed to blow mold a traditional bottle and can be delivered as roll stock to a filling facility, meaning it is easier to ship throughout the supply chain. In addition to significantly reducing plastic at the source, the Chicago-based company’s vision is to be 100% recycle ready by 2025. While enabling seamless, edge-to-edge artwork, AeroFlexx also features a no-leak, self-sealing valve that offers easy, one-handed operation by the consumer.

Loop platform touts reusability

New Jersey recycler TerraCycle Inc., meanwhile, is taking a completely different approach with its Loop circular shopping platform. Loop has gained support from many of the world’s best-known brands, ranging from Unilever, PepsiCo, and Nestlé to Danone, Procter & Gamble, and UPS.

The Loop system uses UPS to ship a variety of food, household cleaning, and personal-care products in a reusable and collapsible, padded container called the Loop tote. The products are dispensed from reusable containers, which are returned in the same reusable tote when empty. Some have dubbed it “the milkman model,” in a nod to the old days when milk was delivered to your doorstep in glass bottles, which were later collected, cleaned, and reused.

“Loop,” maintains TerraCycle founder and CEO Tom Szaky, “is an engine for CPGs to shift from disposable products that consumers own to durable ones they borrow.” The brand owners, meanwhile, actually own the package, which is meant to be reused at least 100 times. The impact on packaging is obvious – instead of trying to make the cheapest possible disposable package or container, the brands are incentivised instead to design handsome, reusable containers out of durable materials.

Numerous companies are also investing in initiatives and technologies to advance both mechanical and chemical recycling and to develop biocompatible and compostable materials.

See you at CHINAPLAS 2021

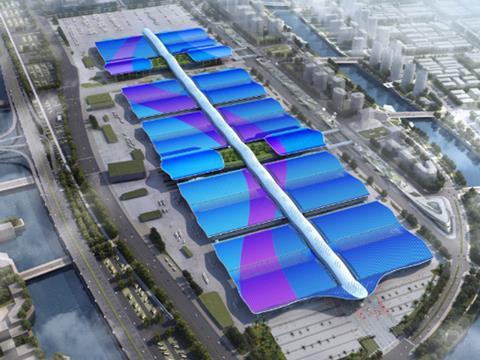

CHINAPLAS is further postponed to April 13-16, 2021 to be held in the Shenzhen World Exhibition & Convention Center, PR China. Focusing on “Smart Manufacturing”, “Innovative Materials”, and “Green & Circular Solutions”, the organizer is expected to present 400,000 square meters of exhibition space. For more information about CHINAPLAS 2021, please visit www.ChinaplasOnline.com.