Although they make up a relatively low proportion of the total weight or volume of a pack, adhesives tapes can make a huge difference in terms of overall sustainability performance. Sreeparna Das, Sustainability Communications Consultant at Afera, tells us more.

Packaging is indispensable in today’s modern world. The rapid expansion of e-commerce and food delivery services in recent times has further fuelled the growing demand for packaging. They offer several benefits like product protection (especially during transportation and storage), the extension of shelf-life of perishables (reducing food wastage), hygiene maintenance, traceability, and more.

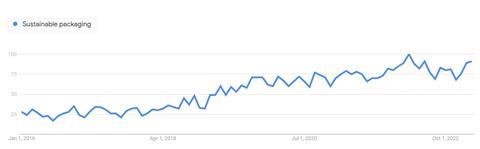

In the past, the functional requirements of the product and the aesthetic needs of the brands largely dominated the thought behind packaging designs. Now, in the face of the packaging waste crisis, sustainability is a key factor, and demand for sustainable packaging solutions is significantly growing.

Fig. 1. Topic search: ‘Sustainable Packaging’ on Google. Worldwide interest over time shows a consistent rise with a significant peak in March 2022

Source: Google trends

Packaging designs are undergoing a makeover, with the industry adopting innovative approaches to improve their green credentials. From eco-design concepts that enable reuse, refill, and recycling to the overall reduction of packaging used for a product, a lot is going on.

Adhesive tapes, thanks to their flexibility and highly functional nature, can adapt to support the rapidly evolving sustainability requirements of the packaging industry.

Before getting to specific examples highlighting the role of tapes as facilitators of sustainability, let’s first take a look at the packaging trends and sustainability drivers.

Sustainable packaging trends

Consumer demand and regulatory pressure are the key drivers here. In Europe specifically, the Packaging and Packaging Waste Regulation (PPWR) – set to come into effect in 2024 – will have a major impact on the packaging value chain. Along with several other targets, the latest revision of the EU legislation mandates that by 2030:

- All packaging materials should be reusable or recyclable

- Each unit of packaging should be scaled down to its minimum size by weight, volume, and layers of packaging

- Plastic packaging should contain a minimum % of recycled content recovered from post-consumer plastic waste (targets set per application type)

As a result of these targets, the two emerging trends in the packaging and beverage industry are ‘minimisation’ and ‘paper-isation’!

An example that highlights both these trends is that of the “Green Grip” launched by Heineken (see Fig. 2.). The recyclable cardboard-based secondary packaging allows Heineken to replace single-use plastic rings and printed plastic shrink wrap, minimise the use of materials, and reduce waste.

Fig. 2. New secondary packaging solution minimises material use and replaces single-use plastics

Image credit: Heineken

Another innovation in secondary packaging reduction can be seen with the KHS Nature MultiPack. Accurately-placed adhesive dots and a carry handle tape enable packaging reduction of up to 85% compared to systems that use cardboard, while maintaining pack integrity from production to consumer.

Fig. 3. KHS Nature MultiPack featuring up to 85% less packaging compared to systems that use cardboard

Image credit: H.B. Fuller

‘Invisible’ facilitators of packaging sustainability

Though a small part of the complete packaging unit, adhesive tapes provide functional support in various packing applications. By using traceable packing tapes, businesses can easily track, store, and group their consignments. Also, business owners can use it for branding purposes.

As part of tamper-resistant seals, packaging tapes can enable product safety during transit and also cater to the growing demand for tamper-evident food packaging.

By choosing the right kind of tape, it is possible to reduce the overall use of materials and resources and incorporate more recyclable materials in package designs.

“As the industry moves toward sustainable packaging designs, adhesive tapes can play an important role because of the functional benefits they offer. Tapes can facilitate the change from one packaging design philosophy to another because they are so flexible. Their flexibility means that as the packaging requirements evolve, tapes can evolve with them. Also, it is possible to reduce the overall amount of packaging with the clever use of tape,” says Jeff Burrington, Senior Application Specialist, H.B Fuller.

Partners for product circularity

The following examples show how adhesive tapes also facilitate packaging circularity.

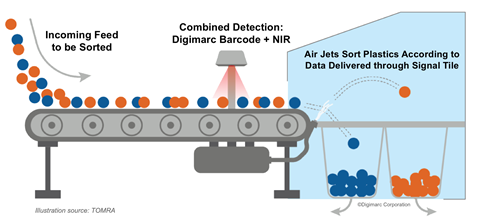

The Holygrail 2.0 project is an initiative of the European brand association AIM supported by the Alliance to End Plastic Waste (AEPW). The project aims to prove the viability of digital watermarking technologies to enable accurate sorting, thereby, improving post-consumer packaging recycling. As part of the project, Novacel’s pressure-sensitive adhesive (PSA) tapes were successfully printed with digital watermark to facilitate advanced plastic sorting. This way, sorting plastic by food and non-food contact becomes possible, enabling higher-quality recyclates for circular use.

Fig.4. Digital watermarking technologies to enable accurate sorting of post-consumer packaging waste

Image credit: Digimarc Corporation and TOMRA

The second example comes from H.B. Fuller. They have designed a new fibre-based tear tape for paper-based e-commerce packaging. Unlike other plastic tapes, this fibre-based solution recycles directly with the board and adds usable fibre to the recycling stream. This enables a mono-material recycling stream, supporting the circular economy.

Fig.5. Sustainable solution for e-commerce packaging

Image credit: H.B. Fuller

Supporting recycled content targets in plastic packaging

With a focus on material circularity, the adhesive tape industry has launched several new products in recent years that feature both post-industrial and post-consumer recycled plastic content.

Future outlook

For the entire packaging value chain, design guidelines for recycling and circularity are currently available from industry associations like RecyClass, CEFLEX, and 4evergreen (as part of CEPI). In the lead-up to 2030, the European Commission is expected to adopt delegated acts establishing ‘Design for Recycling’ (DfR) criteria and Performance grades (A to E). All packaging must meet the DfR guidelines by 2030 and if the packaging is considered <70% recyclable (performance grade E), it will be considered not recyclable.

Afera, through its Flagship Sustainability Project (AFSP), is keeping a close watch on these design guidelines. Preparing DfR guidelines for packaging tape manufacturers and converters is part of the key project deliverables planned for this year. Additionally, Afera’s Test Methods Working Group is also developing methodologies to evaluate the recyclability of fibre-based packaging containing adhesive tapes. For more information: https://afera.com/adhesive-tapes-sustainability/flagship-sustainability-project/

No comments yet