Power Adhesives claims to have developed the ‘world’s first’ fully-certified biodegradable, shaped hot melt adhesive with the aim of boosting the environmental credentials of its product portfolio.

The certified tecbond 214B adhesive claims to break down in prolonged exposure to oxygen, ultraviolet light, and heat. The long-chain polymers in the polymers are broken down to be consumed by microorganisms in a natural decomposition process.

As the adhesive is made with 44% biobased materials, it is said to leave no microplastics or harmful products behind when it decomposes. It is certified in line with ASTM D6400, marking it as an industrially compostable solid material; EN13432, which examines eco-toxicity in soil upon degradation; ASTM D6954, which tests plastics for their degradability; and ASTM D6866, which determines a sample’s biobased or biogenic carbon content.

Due to the absence of organic solvents and harmful chemicals, tecbond 214B can be applied without the use of respiratory PPE.

tecbond 214B is said to match the performance and characteristics of standard adhesives. Once applied and compressed, it apparently forms an instance bond with a high level of tack and fast setting speeds; this is expected to fast-track companies’ packaging procedures and improve workflow and output.

The adhesive is also approved for indirect food contact. It is therefore suitable for use in wrap-around cartons, boxes, shipping packages, and other food packaging applications.

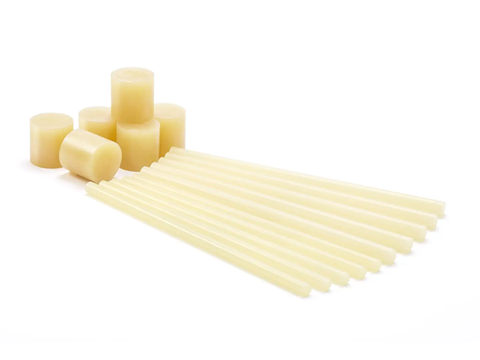

“The work has included detailed formulation, evaluation, and long-term testing in the laboratory and field,” explains Keith Hampson, operations director at Power Adhesives. He adds that “two production lines have been modified to produce the new biodegradable adhesive in 12, 15, and 43 mm sizes.”

CEO Brendan Colgan adds that tecbond 214B is “one of Power Adhesvies’ biggest steps forward in sustainable product development”, with the company aiming to “lead by example in the production and use of biodegradable adhesives.”

It is advised that, until it is ready for use, users keep tecbond 214B in its original packaging and store it out of direct sunlight in temperatures below 30°C. Power Adhesives also suggests the adhesive’s use with its range of tec glue guns to achieve the highest output possible.

tecbond 214B is now available worldwide.

Earlier this year, Flow Materials released its own range of solvent-free, water-based adhesive solutions for flexible packaging, setting its sights on more sustainable sealing for packaging designs.

Since then, Dow, Henkel Adhesive Technologies, and Kraton Corporation have joined forces to reduce the carbon footprint of Henkel’s TECHNOMELT SUPRA 100 LE and TECHNOMELT SUPRA 106M LE formulas hot melt adhesive formulas for end-of-line packaging. Each comes with a biobased alternative and are said to reduce adhesives’ cradle-to-gate carbon footprint by 25%.

Trinseo has also launched LIGOS A 9200, an acrylic waterborne adhesive intended for dry lamination in flexible, food-contact packaging structures. LIGOS A 9200 is tailored for paper and polyolefins, polyvinylidene chloride-coated substrates, metalized film, polyamide, and polyester films.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Reuse vs. single use – which is better for the environment?

The ultimate guide to global plastic sustainability regulation

No comments yet