Horizontal form-fill-seal solutions provider Volpak and Lecta, a specialty papers manufacturer and distributor, have announced a collaborative project aiming to test and validate sustainable materials for packaging applications.

Lecta says the collaboration with Volpak hopes to ensure that new ‘environmentally friendly’ materials can be effectively utilized on existing packaging machinery. The partnership aims to make sure that ‘eco-friendly’ papers meet the operational requirements of modern packaging lines.

The company states that the shift towards sustainable packaging is being driven by both regulatory pressures and consumer demand, citing a report from Bain & Company which says that 71% of European consumers (and a similar percentage of US consumers) express a preference for purchasing sustainable products; many favour products that use minimal or recyclable packaging. Lecta adds that a study by NIQ and McKinsey found that 92% of shoppers consider sustainability an important factor when choosing a brand.

Both Volpak and Lecta hope that, by focusing on recyclable paper-based packaging, they can address these consumer preferences and contribute to a reduction in packaging’s environmental impact.

Lecta has reportedly utilized its technological knowledge and production capabilities to create new metallized, uncoated and coated one side papers with barrier properties, designed to maintain eco-friendly characteristics while providing essential protections, such as barriers against water vapour, grease, oxygen, and alcohol. The papers are said to be recyclable and can be processed in standard paper recycling circuits.

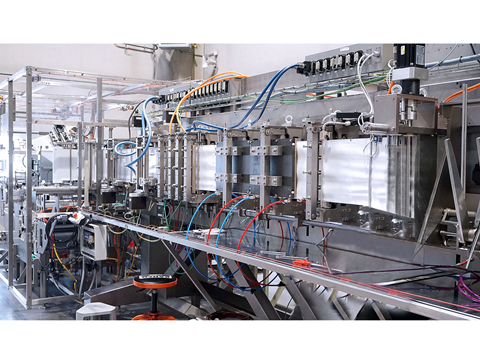

The primary focus of the joint project is to explore the use of Lecta’s papers in flexible packaging, with potential applications in various sectors including food service items such as cups. Volpak’s role involves conducting tests to assess the performance of these materials in real-world scenarios, carried out within Volpak’s “pouch lab,” an internal research and development facility designed to evaluate the machinability and durability of new materials.

Currently, both companies are engaged in trials to evaluate the effectiveness of the new papers, which they say are crucial for identifying potential improvements and obtaining the necessary certifications for commercial use.

In similar news, Coveris recently introduced its MonoFlex Fibre packaging range of paper-based, pre-made bags and form-fill-seal solutions. It aims to help customers transition into high-barrier yet recyclable packaging solutions in compliance with EU regulation. All specifications are said to be recyclable and provide the ‘right level’ of protection and barrier properties against grease, moisture, oxygen, light, or mineral oils.

Earlier in the year, Parkside announced its Recoflex range of recyclable, paper-based flexible packaging materials, said to offer durability, barrier performance, and heat sealability in several market applications. The new range of papers are available as a single-ply or laminate in several specifications.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Reuse vs. single use – which is better for the environment?

The ultimate guide to global plastic sustainability regulation

No comments yet