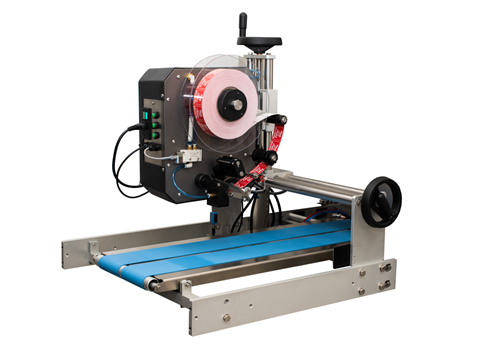

Ravenwood has revealed its new promotional flash labeller as a standalone applicator or as an integrated option with any linerless applicator in the Nobac 5000 range.

The Nobac 40 has linerless capability and is said to have ‘superior’ build quality and enhanced component tolerance. Ravenwood aims to present the machine as an affordable solution with a competitive price point in the market.

The company says compared to traditional labels with liners, linerless labels are an ‘eco-friendly’ option for various food sectors, as they don’t require backing paper on the reel – they adhere to themselves using matching strips of adhesive and silicone applied to the underside and face of the label.

Ravenwood states this design reduces material usage, waste, and CO2 emissions. It adds that the Nobac 40 applies flash labels to Modified Atmosphere Packaging (MAP) packs to the top, side, or base of the product, with line speeds reaching 30 metres per minute, equating to around 130 labelled packs.

The linerless labeller is designed for high-output operations and applying promotional labels in real-time during the packaging process without slowing down the production line. Its control systems are said to ensure accurate label placement, important for maintaining consistency in product presentation and avoiding misaligned labels that could impact the product’s appearance. Various mounting options are available.

Paul Beamish, Ravenwood’s managing director, said: “We are thrilled to introduce this industry-first linerless flash label solution. Now, when customers purchase a Nobac sleever, we’re able to offer them a linerless flash labeller instead of a self-adhesive machine.”

Videojet launched its new 9560 automated labelling system in July, which prints and applies labels to outer cases, boxes and shrink wrap. The system is said to feature increased processing speeds and expanded connectivity options, also aiming to improve operating performance with a direct drive that controls label speed and position without clutches, rollers or adjustments.

More recently, Sappi Europe added a linen-embossed version of its Parade Label WS paper label to its portfolio of wet-glue wet-strength label papers. The addition is said to achieve precision and speed for premium brands and achieve ‘excellent’ results in printing and converting operations.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet