Six packaging papers from UPM Specialty Papers have been certified as both home and industrially compostable in line with French legislation – a move set to ensure the responsible, environmentally safe treatment of paper packaging solutions at end-of-life.

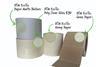

Three of the papers are coated on one side (C1S). This includes UPM FlexPack, a high white paper for food packaging designed especially for flexo printing; UPM UniquePack, a glossy paper for high-end packaging compatible with flexo and rotogravure printing, alongside a range of lamination processes; and UPM UniquePack Strong for durable and aesthetically pleasing flexo-printed packaging.

Two barrier papers – UPM Prego, a water vapour barrier paper for baked goods and food to go, and UPM Asendo, a C1S barrier paper with grease and moisture resistance – have also been named as compostable.

UPM Solide Lucent specialty kraft paper completes the list. It is natural white and translucent, described as a versatile material for converting and printing applications.

The papers are certified as home and industrially compostable according to French standards NF T-51-800 and EN 13432, respectively. Both fall under article 75 of the Law on Energy Transition for Green Growth, which forbids oxo-fragmentable packaging – or packaging made from conventional plastics with additives to make the material degradable, yet lacking the natural microorganisms to truly break it down.

UPM hopes that its recyclable, fibre-based materials will help brand owners and converters embrace home compostability. It explains that home compostable materials are designed to biodegrade within twelve months and disintegrate into non-ecotoxic compost within six months, at temperatures between 20°C and 30°C.

However, the company warns that compostability is not a silver bullet in the pursuit of more sustainable packaging.

“Recycling should always be the first option to consider when possible,” explains Susanna Hyrkäs, senior manager of Sustainability at UPM Specialty Papers. “However, compostability is a good option when recycling of packaging papers is not possible due to food residues, for example. Compostability can also play a role when recycling infrastructure is limited.”

Recyclability and compostability also fit into UPM’s responsibility targets for 2030, including the pursuit of a circular economy and designing products for sustainability, by considering a product’s treatment at end-of-life.

The company has also received home and industrial compostability certification for two of its label face papers, UPM LabelCoat and UPM LabelCoat Prime, in line with the compostability and recyclability requirements of the Packaging and Packaging Waste Regulation.

In additional news, Mondi recently announced that its entire kraft paper packaging portfolio has been certified as home or industrially compostable. The achievement has beaten the company’s own target of making all its packaging and paper products compostable by 2025.

If you liked this article, you might also enjoy:

The L’Oréal approach to packaging sustainability

What steps is Apple taking to make its packaging more sustainable?

How did Brazil achieve its 100% aluminium can recycling rate – and can it be replicated in the EU?

Experts have their say on the EU’s Packaging and Packaging Waste Directive revisions

No comments yet