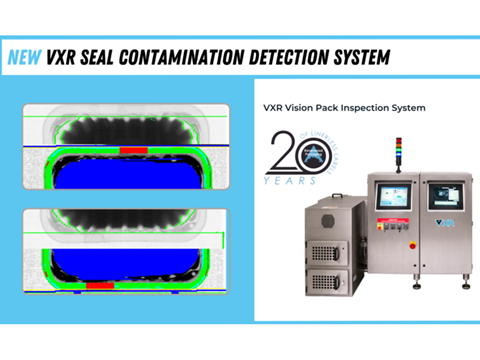

Ravenwood has announced the development of a seal detection software for its VXR vision pack inspection system, said to guarantee ‘100% accuracy’ and protect brand owners from financial loss, product recalls, and heavy fines.

The new detection software is available to existing VXR customers and can also be ordered as an optional feature on new machines. Ravenwood says that its X-ray inspection technology allows for both standard product contamination checks and seal contamination detection. It adds that contaminated packs that reach supermarket shelves can lead to rapid product spoilage and reduced shelf life.

The company states that detecting seal contamination is particularly difficult at high running speeds, and when there is minimal colour contrast between the contaminant and the tray (such as beef in black MAP trays), detection becomes more challenging, especially with optical camera-based systems.

The seal contamination inspection system is said to operate automatically with minimal operator input, ensuring thorough checks on each pack even at high line speeds. It integrates standard X-ray capabilities, displaying two images on the VXR interface: one for standard X-ray contamination detection and another for the new seal contamination detection.

The solution is available as a standalone unit with Vision (or Vision alone) and can be integrated with the Ravenwood Nobac 5000 range of linerless label applicators.

James Large, Ravenwood’s VXR and vision product manager, said: “The VXR’s fault-finding capabilities far surpass those of traditional methods that rely on human visual checks and camera-based systems. By utilising X-ray inspection technology to check for density variations in the seal area, it is now possible to detect even the smallest amounts of contamination, whether from the product itself or a foreign body in the pack seal.”

Last year, researchers at McMaster University in Canada announced the creation of a new packaging tray that can signal when Salmonella or other dangerous pathogens are present in packages of raw or cooked food, such as chicken. The developers said the new technology was expected to enable producers, retailers and consumers to tell, in real-time, if the contents of a sealed food package are contaminated without having to open it.

This year, Eco-Products launched a new product line designed to make differentiation between compostable and non-compostable products easier for consumers, composters, and the foodservice value chain. All items are designed to meet new labelling rules requiring the use of the word “compostable,” a third-party certification mark, and a combination of colour and design elements that vary by state. Apparently, the laws were created to address contamination challenges and make compostable foodservice products more readily and easily identifiable.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Reuse vs. single use – which is better for the environment?

The ultimate guide to global plastic sustainability regulation

No comments yet