Linx Printing Technologies has developed two new inks to print legible, durable codes onto the ‘latest generation’ of recycled and recyclable plastic films and increase traceability across customers’ supply chains.

Simon Millett, inks product manager at Linx Printing Technologies, explained: “Legislative changes including new plastic taxes, together with retailer and consumer demands, are driving manufacturers to reduce their use of plastic, and this has led to a move towards stronger laminated plastic films and more recycled and recyclable packaging.

“As a result, we are seeing the introduction of thin flexible plastic wrapping and pouches of OPP, BOPP, HDPE and LDPE, but these can present a challenge for ink adhesion, and many general-purpose inks do not stick effectively to these lower surface energy plastics. This means that codes may smudge, scratch, or rub off in production or transit, which can lead to reworking, rejects and even fines.”

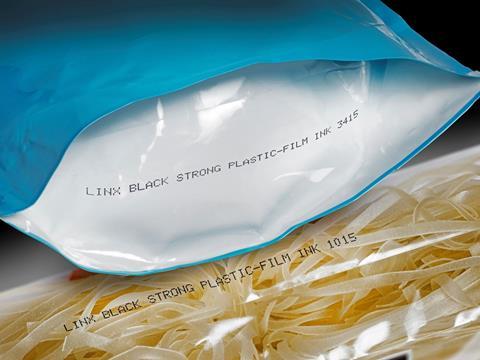

In response, Linx Black Strong Plastic-Film Ink 1015 and Linx Black Strong Plastic-Film Ink 3415 are intended to offer reliable code adhesion on plastic film packaging, including plastic flow wrap for dry foods and plastic pouches for food sauces, confectionery, pet foods and household chemicals.

The inks are said to be PFAS- and CMR-free in compliance with such standards as the European Printing Ink Association (EuPIA) Exclusion Policy, and reportedly balance ‘excellent’ adhesion with legibility and printer reliability. Linx Black Strong Plastic-Film Ink 3415 is formulated as a non-MEK version; methyl ethyl ketone, or MEK, is a volatile organic compound that can negatively impact human health and the environment.

Linx claims to have tested the inks on packaging formats in Australia, China, France, the UK, India, the Philippines, and Poland, among other global regions. It hopes the solutions will address increasing demand from global customers for dependable code adhesion.

“Our team of scientists designed and tested over 100 formulations during the development process, to ensure we devised a truly versatile solution for the widest variety of pack types and applications,” said Dr Amy Ruddlesden, ink development manager and principal chemist at Linx Printing Technologies. “The new Linx Black Strong Plastic-Film Inks 1015 and 3415 will help customers ensure full traceability for their products by ensuring consistent high-quality, easy-to-read codes on today’s flexible plastic packaging.”

In similar news, Needham Ink Technologies revealed its MEK-Free Continuous Inkjet inks last year. These are expected to improve workplace safety, reduce emissions – and, since customers do not need a permit to use the inks, increase accessibility for businesses operating under national laws and restrictions.

More recently, hubergroup Germany attended drupa 2024 with its water-based and food-contact packaging inks – including the MGA CONTACT direct food-contact series, which is apparently safe to use inside paper and cardboard food packaging.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Reuse vs. single use – which is better for the environment?

The ultimate guide to global plastic sustainability regulation

No comments yet