James Cropper’s CupCycling technology is now able to recycle both the plastic and paper from disposable coffee cups, the company claims – an advancement hoped to ensure that the entirety of the cup is recycled.

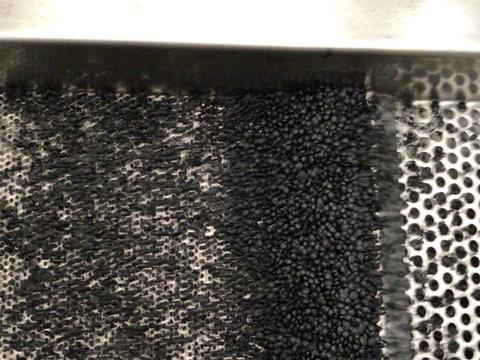

In collaboration with partners Cumbria Waste and New Horizon Plastics in North Wales, James Cropper has apparently overcome the previous restriction of 5% of plastic waste removed from each cup being used for energy recovery in recycled paper production. It can now be converted into pellets and applied to commercial packaging and agricultural applications, amongst others.

This process expects to ensure that the entire cup is recycled, with its paper converted into new paper products and premium packaging. Its recent development also claims to close the loop on CupCycling technology.

With 30% of the 60 million tonnes of plastics produced in Europe thought to be recycled every year and 79% of all plastic waste ever created ending up as litter in the natural environment or as landfill, CupCycling technology hopes to contribute towards a circular economy that could drive down these figures.

“Recognising value in the high quality fibre used to create paper cups, we were inspired to convert this enormous waste stream into a value stream instead, and now we’ve taken it even further,” explains Fibre Operations group leader Rob Tilsley. “Working with our local waste management partner, Cumbria Waste, we have been relentlessly exploring sustainable opportunities where the cup plastic can be recycled or reused locally.

“Following extensive trials, New Horizon tested and approved the plastic waste, which is separated from cups during the CupCycling process, and it is now collected by Cumbria Waste and recycled by them in North Wales.

“New Horizon Plastics, one of the best plastic reprocessing companies in the UK, has the capability to shred, wash and turn the cup’s waste plastic into pellet form. Processing around 155 tonnes of plastic every day, the clean plastic pellets eventually end up in a range of products such as bags and wraps to plastic gates, animal pens and grain stores.

“This work is the result of some fantastic collaborations with partners that have helped us achieve our pledge to the Ellen MacArthur Global Commitment to work to accelerate the transition to a more effective circular economy.

“In addition to being able to recycle 100% of every cup, we have increased our capacity by 40% at our CupCycling plant – allowing us to recycle up to 700 million cups per annum – and have expanded the areas from which we will be collecting cups.”

In support of the Foodservice Packaging Association, James Cropper also expresses its reservations about the UK Department for Environment, Food & Rural Affairs delaying a mandatory paper cup takeback scheme, fearing that it could dissuade retailer support and participation.

“Organisations from across the cup recycling ecosystem have invested heavily in supporting the mandatory takeback scheme,” Tilsley adds. “Seeing this fantastic opportunity delayed is an unnecessary setback.”

Last year, Huhtamaki and Stora Enso launched The Cup Collective, a paper cup recycling initiative aspiring to recycle and capture the value of used paper cups at an industrial scale in Europe. Shortly after, McDonald’s, SSP – The Food Travel Experts, C2 Centre, and the National Railway Company of Belgium became its first members.

Costa Coffee, McDonald’s UK, and Roadchef also worked together to found a takeaway cup collection and recycling programme. The cups were sent to James Cropper’s specialist facilities to be recycled into stationery and paper packaging.

If you liked this article, you might also enjoy:

The Lidl approach to packaging sustainability

How did Brazil achieve its 100% aluminium can recycling rate – and can it be replicated in the EU?

Experts have their say on the EU’s Packaging and Packaging Waste Directive revisions

A deep dive into the most important packaging sustainability trends and solution

No comments yet