MPS Systems B.V., the globally renowned Dutch-based printing press manufacturer, is set to launch several new innovative technology initiatives with key industry partners at Labelexpo Europe, taking place September 25-28 in Brussels, Belgium.

Ground-breaking connectivity technology, process advancements in job automation, and the new Semi-Rotary Quick Change Die solution will be shown on the MPS stand 11C20 and in the Automation Arena.

Bert van den Brink, co-founder and technical director at MPS said: “Workflow management is a key theme behind the MPS technologies that will be presented at Labelexpo Europe. We’ve partnered with many industry suppliers that are equally driven in providing automation to the printing process, to build solutions that will help printers and converters maximize efficiencies in their overall production environment.”

‘talk to me’ – connectivity by MPS

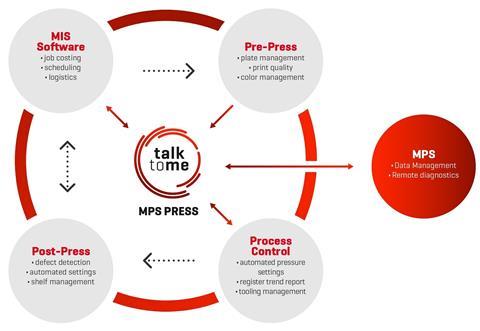

A new connectivity platform ‘talk to me’ that promotes interaction between MPS printing presses and Management Information Systems (MIS) will be launched at Labelexpo Europe. An innovative new concept developed by MPS, ‘talk to me’ is a break-through in the integration of all software and equipment on the print shop floor. Communication between equipment is becoming increasingly important, considering the growing shortage of skilled operators. Automating the various processes, from pre-press to printing through to the final post-press stages, is a benefit to operators and business owners.

Van den Brink explained: “We will show the latest developments in connectivity with certain partners. However, ‘talk to me’ is an ongoing development initiative, and open to other partners and their automation solutions. I invite all Labelexpo visitors on the MPS stand to get to know ‘talk to me’, and discover the advantages for their business.”

The Management Information System (MIS) is the link between all systems and software on the print shop floor. CERM or Labeltraxx (MIS) sends the job information via pre-press to the MPS press, and receives machine information back from the press. Together with the AVT inspection system, a quality report can be retrieved from the MIS. This report can also be used for all other connected equipment, to share information about the various processes. To guarantee product quality, the AVT 100% inspection camera checks the default in print results compared to the print job file, which is taken from the pre-press. The inspection system connects the press with the post-press department. Esko colour management and workflow management are important in the pre-press stage of the process. The automation engine sends information to the press for automated job configuration.

In the process control stage, AVT Presco measures the pressure settings of the anilox and print sleeves. Together with Apex, MPS developed Smart Anilox equipped with RFID.

In MIS, the RFID specifications can be read to evaluate the history and apply preventive maintenance. Finally, in the post-press stage, defect detection systems and shelf management can be connected to the ‘talk to me’ circle.

All systems are connected through the MPS ‘talk to me’ connectivity platform, allowing for real-time data exchange and control at any given moment, and contributing to optimization of the total printing process.

The MPS press is also connected to the MPS office for support, preventive maintenance, data management and service through remote diagnostics.

Live demonstrations of ‘talk to me’

Four times daily during Labelexpo Europe, MPS will present on its stand 11C20 a combined live demonstration of the EF automated multi-substrate flexo press and the hybrid flexo/digital EF SYMJET press developed with Domino.

During these live demonstrations, the ‘talk to me’ connectivity concept will be demonstrated, showing minimal operator involvement after initial log-in to a unique operator interface, to automatically load the operator’s personal job settings. Visitors are invited to follow the press performance, including speed and print job information, in real-time on their ‘talk to me’ app. The app will be available for smartphones from the App Store and Google Play Store.

Automation Arena — Tomorrow's promise... today's reality

Located close to the MPS booth in hall 11 is the debut of Automation Arena, featuring two automated press lines for digital and conventional label production. MPS will show a fully-equipped EF multi-substrate press together with other automated solutions from a team of suppliers including Xeikon, Kocher & Beck, CERM and AVT, to simulate a completely automated print shop floor. Demonstrated will be the automated processes from pre-press job creation, quality checks, to conventional- and digital print runs, all the way to post-press, warehousing and invoicing.

Demonstrations at the Automation Arena will be held three times daily Monday-Wednesday and once on Thursday.

New semi-rotary die solution

Also making a debut at Labelexpo Europe is the new MPS Semi-Rotary Quick Change Die unit. Based on the well-known MPS Quick Change Die, this solution features semi-rotary operation at speed up to 65 m/min (also possible to run as full-rotary), an integrated plate changing tool for quick change-over of magnetic die plates without changing the die cylinder, and reduced tooling cost. This new die change solution is completely connected with ‘talk to me’ technology, as job settings can be downloaded into job memory.

Available for the entire EF gamut, the Semi-Rotary Quick Change Die will be shown at Labelexpo Europe on the EF SYMJET to further highlight its advantage in hybrid printing.

More info: